Press release / 2019

Fraunhofer WKI is part of the transregional DFG Collaborative Research Centre “Additive Manufacturing in Construction”

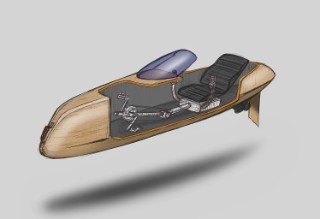

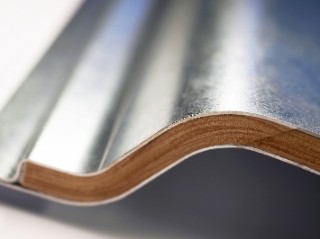

The Deutsche Forschungsgemeinschaft (DFG, German research foundation) is supporting a transregional Collaborative Research Centre (CRC) of the Technische Universität Braunschweig and the Technical University of Munich. Dr. Frauke Bunzel from the Fraunhofer Institute for Wood Research, Wilhelm-Klauditz-Institut WKI and Dr. Klaudius Henke from the Technical University of Munich will jointly lead the sub-project “Structural timber by individual layer fabrication (ILF)”.

more info Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research