Press release

50th Fraunhofer WKI Webinar – Research in interactive public dialogue

On May 21st 2019, the 50th Webinar from the Fraunhofer Institute for Wood Research, Wilhelm-Klauditz-Institut WKI will take place from 3 pm to 4 pm. Since November 2011, interested parties have been able to obtain information concerning current research through the free Webinars. The topic of the anniversary Webinar is “Crack formation in melamine resin coatings”.

The topics of the 50 Webinars illustrate the research diversity of the institute and have included, amongst others: “Formaldehyde-free adhesives in the wood-based materials industry”, “Thermography on rotor blades”, “Itaconic acid as a sustainable building block for UV-curing printing inks”, “Hybrid structures incorporated with wood-chip concrete for sustainable construction” and “(Bio-)plastics for the timber industry”. The Fraunhofer WKI Webinars increase the transparency of projects, some of which are publicly funded, and provide industrial customers with valuable inspiration. “The researchers at the Fraunhofer WKI take the opportunity offered by the Webinars to report on research results and to enter into a dialogue with a wider public,” explains Heike Pichlmeier, organizer of the Webinars at the Fraunhofer WKI.

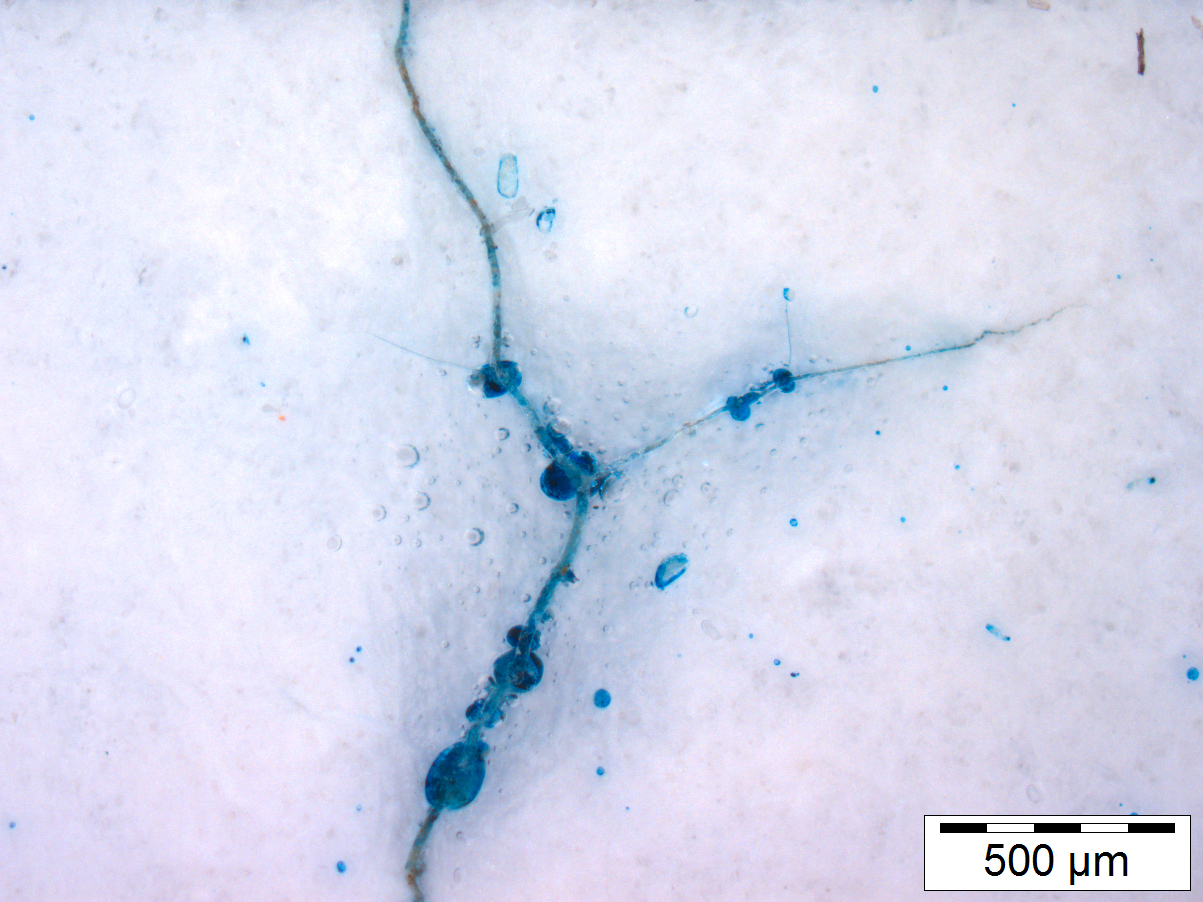

The 50th Webinar will address coatings on the basis of melamine resin, which are extremely resistant. They are utilized in diverse applications as a protective surface layer on kitchen worktops, doors, laminate floorings and furniture. These are either direct-coated wood-based materials, such as particle board and laminated veneer lumber board, or laminates such as HPL (high pressure laminate) and CPL (continuous pressure laminate). In rare cases, however, cracks can occur, thereby causing very high costs.

In close cooperation with industry, Fraunhofer WKI researchers have investigated the formation of such cracks in order to be able to counteract this problem in the future. Until now, virtually no scientific knowledge has existed concerning the properties of the hardened materials and the influence of process parameters. By means of an optimized quantification method and statistical test planning, the researchers at the Fraunhofer WKI have identified, amongst other things, the degree of curing, the moisture content of the materials and the particle size of the surface layer as important influencing parameters for crack formation.

In addition, they have also further developed two procedures. For surface testing of the crack resistance of direct coatings, the standard test has been modified, whereby a considerably improved differentiation and evaluation is enabled. In order to determine the degree of curing of the resin, a method already partially applied by the industry has been further developed. The optimization leads to a faster and more precise determination of the curing degree and therefore to an optimized machine control.

The Webinar is aimed at producers of melamine resin coatings and wood-based materials as well as suppliers and testing laboratories.

Background: Fraunhofer WKI

Sustainability through the utilization of renewable raw materials has formed the focus at the Fraunhofer WKI for more than 70 years. The institute, with locations in Braunschweig, Hanover and Wolfsburg, specializes in process engineering, natural-fiber composites, wood and emission protection, quality assurance of wood products, material and product testing, recycling procedures and the utilization of organic building materials and wood in construction. Virtually all the procedures and materials resulting from the research activities are applied industrially.

Last modified:

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research