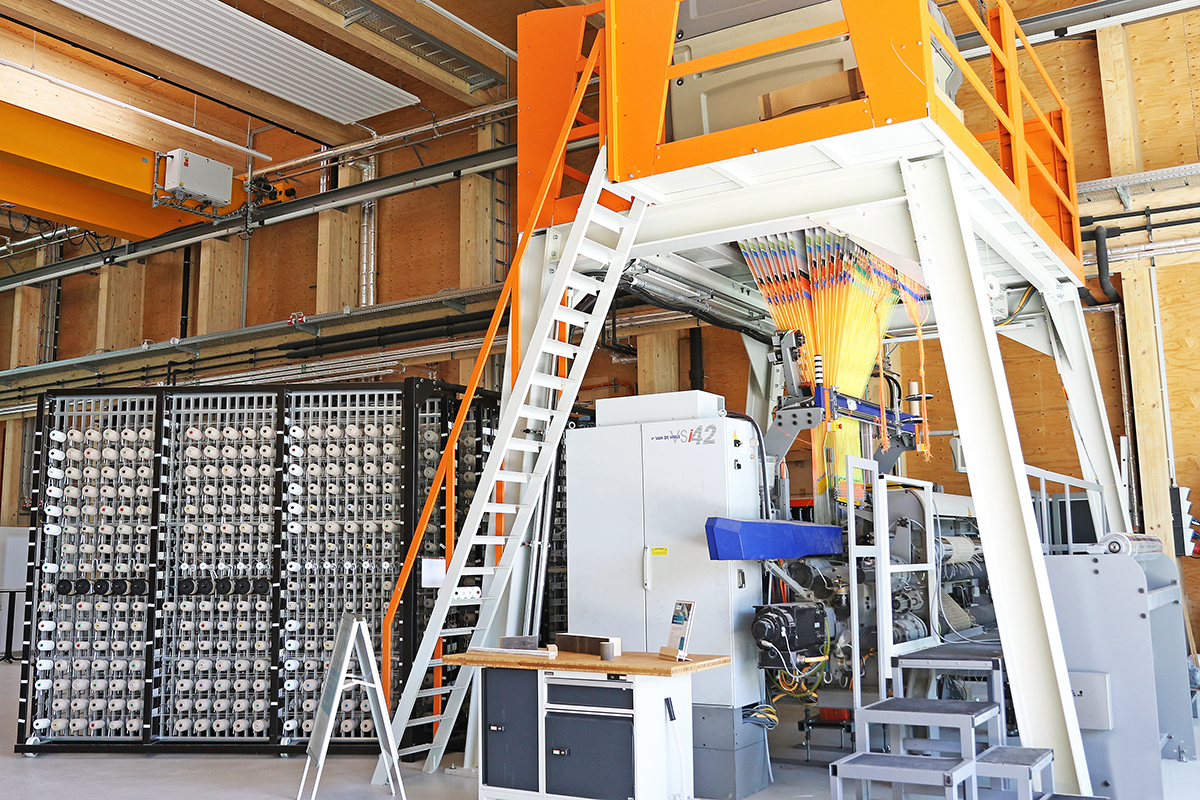

With the aid of the double-rapier weaving machine with Jacquard we are able to produce innovative lightweight composite materials with complex, application-specific fabric structures and integrated functions. This machine enables the efficient and technically complex combination of conventional and sustainable materials. Areas of application are primarily the automotive, construction and leisure industries as well as all fields in which composite materials achieve an advantage.

Double-rapier weaving machine

Location: Braunschweig (ZELUBA®)

By means of the complex weaving technique, we can produce fabrics of differing weaves from yarns, filaments and rovings. The modern Jacquard technology makes it possible to individually control the yarns which are to be processed, thereby enabling the realization of an enormous weave diversity. With the weaving machine, it is also possible to produce multilayer fabrics and three-dimensional structures in one working step. In addition to conventional reinforcing fibers such as carbon and glass, natural fibers can also be combined with one another within the fabrics in one step. These so-called hybrid fabrics specifically unite the advantages of bio-based materials with those of conventional fibers. As regards a subsequent processing to form composite materials, the direct utilization of thermoplastic yarns in the weaving process is furthermore possible. In a subsequent step, these can be directly further processed through a thermoforming process. In addition, functions can be integrated directly into the fabric or the semi-finished product. These can, for example, be conductive yarns or wires, which serve as sensors or conducting paths. Through the simultaneous processing of different materials, diverse working steps can be aggregated and production costs can be substantially reduced.

Technical data

- Double rapier

- Jacquard attachment

- Realization of weave widths of up to 50 cm

- Creel for 3456 spools

Production possibilities for technical fabrics

- Two-dimensional fabrics

- Multi-layer fabrics

- Spacer fabrics (spacings up to 40 mm)

- Hybrid fabrics

- Integration of matrix yarns in textile semi-finished products

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research