Additive manufacturing processes such or 3D printing are highly is primarily used in rapid prototyping, but is also becoming increasingly important in series production. We develop innovative polymeric materials made from renewable raw materials for additive manufacturing. Our focus is on UV-curing processes. Our services are aimed at material developers, manufacturers of 3D printers and users in the construction, automotive, transportation and electronics industries.

Materials for additive manufacturing processes

Research topic

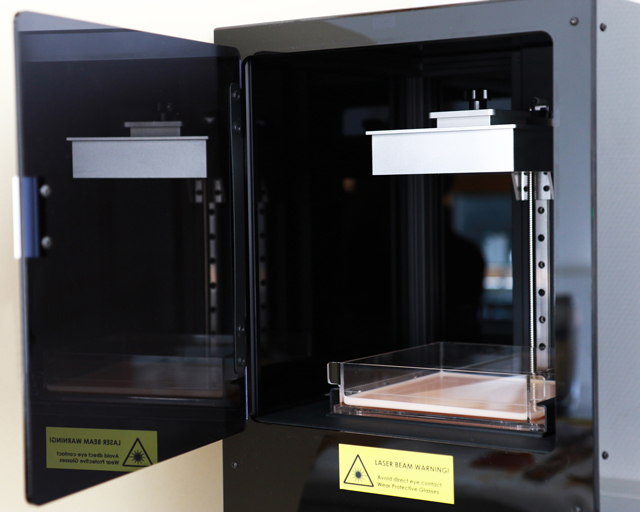

UV-curing processes (SLA, DLP and MJM)

Within the field of UV-curing processes, we develop new polymer resins with bio-based building blocks which cannot be produced through petrochemical means. In this way, we are expanding the material variety and the possibilities for the additive manufacture of sustainable components. Furthermore, we specifically exploit the advantageous properties of bio-based polymers. They can be used to create UV-curing printing materials that have improved properties compared to conventional materials, such as temperature resistance and UV stability. They can be utilized for UV-curing processes such as stereolithography (SLA), digital light processing (DLP), and multi-jet modeling (MJM).

Pilot production

In our technical center, we process all newly developed materials for additive manufacturing into material samples and test them regarding the desired properties. In collaboration with our customers, we develop technical and ecological advantages over conventional starting materials.

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research