Fiber analytics and modification

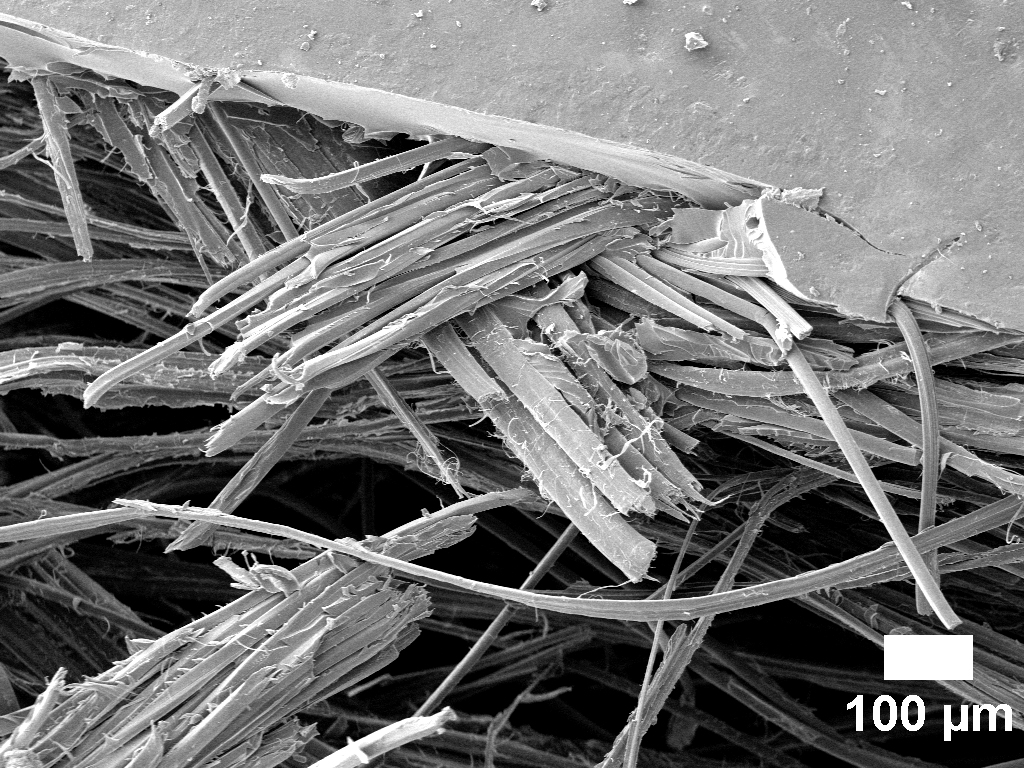

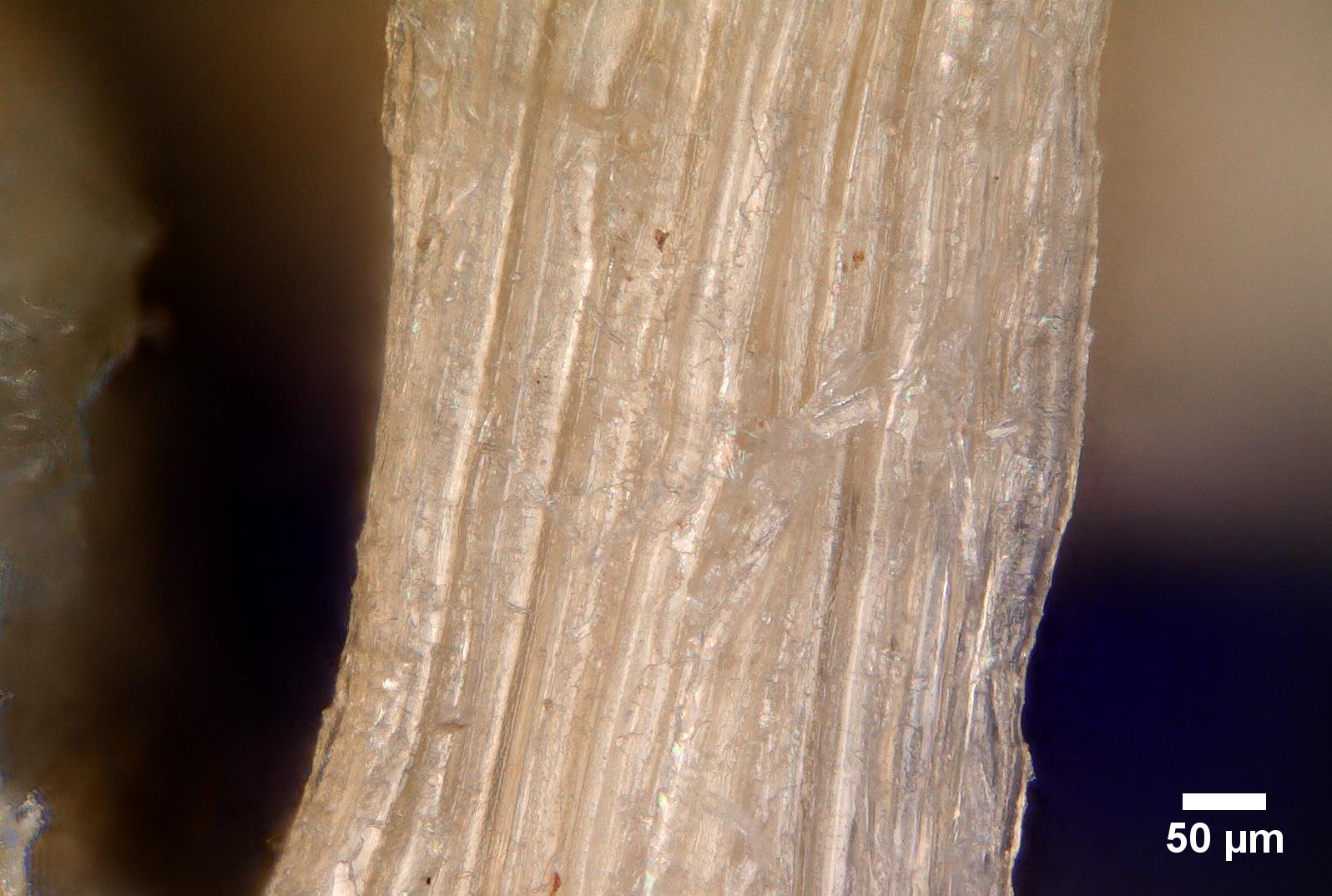

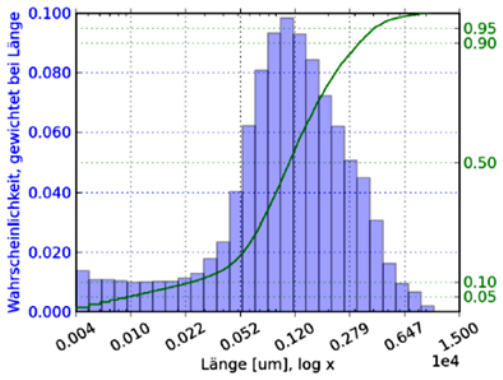

Increasing demands on the functionality, profitability and recyclability of components necessitate the development of innovative hybrid materials such as (bio) fiber composite materials. To ensure a maximum performance potential for these novel materials, the interface quality between fibers and matrix must be optimized. The optimized interface serves the effective transmission of force and ensures a high mechanical resistance in the finished component. At the “Application Center for Wood Fiber Research HOFZET”, we investigate and develop wet-chemical and physical approaches for the surface modification of fibers for the automotive, construction, astronautic and aeronautic industries.

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research