At the Fraunhofer WKI, we use numerical simulations for analyses at the material, component and system level. In addition to mechanical models, the spectrum of our fields of application thereby also includes the calculation of moisture and thermal transport processes as well as fluid-mechanical examinations. A further core competence lies in the coupling of physical problems, which provides us with a holistic view of complex issues. Due to the interdisciplinary fields of application, the ZELUBA® simulation team works closely with the other specialist departments of the Institute.

The demands placed upon the simulation software differ widely depending on the problem and the application purpose. We have access to a variety of programs which we deploy in accordance with the individual case. For the verification of the plausibility of simulations and to compare them with reality, the results are always validated through real experiments. For this, we have access to diverse testing facilities and measuring techniques in the Technology for Wood and Natural Fiber-Based Materials department. These include, amongst other things, optical measuring techniques.

Mechanics

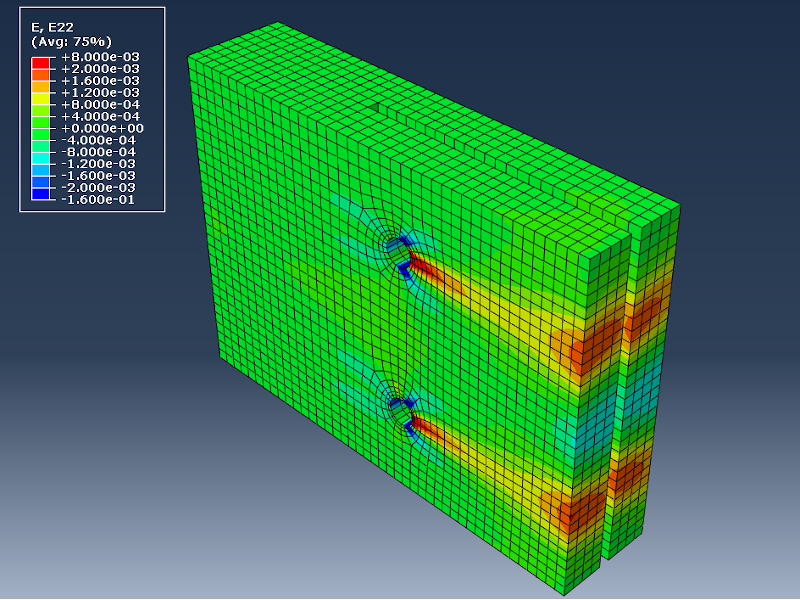

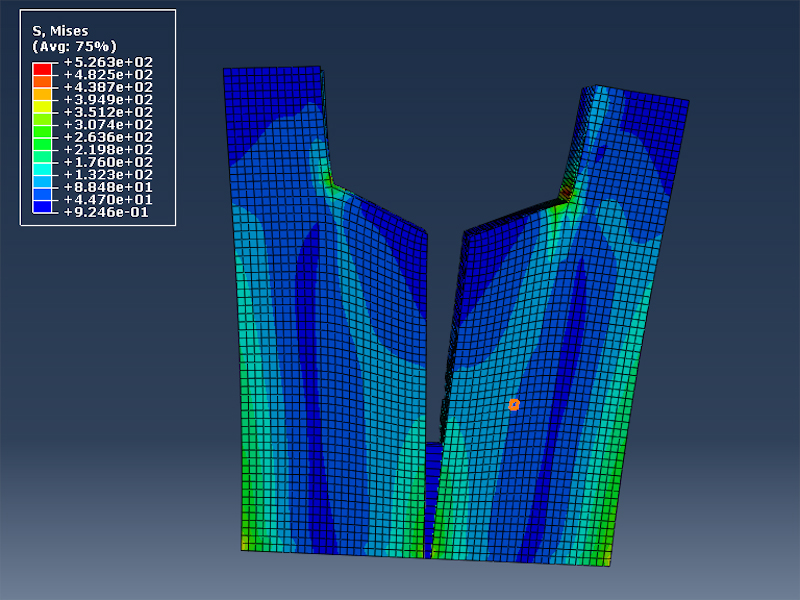

We perform mechanical analyses by means of finite element simulations. These include, for example, investigations into strength, serviceability or vibration behavior in the case of an earthquake. For the calculation of hybrid structures, we have a wide diversity of material models - including non-linear and anisotropic material behavior. We can thereby take into account the fiber orientation in wood and fiber-reinforced materials as well as deformations of a non-elastic nature. Crack propagation and the mechanical behavior of glued joints are modeled using the cohesive-zone method, whilst load-dependent and moisture-dependent creep processes are simulated with the aid of viscoelastic and mechanosorptive formulations.

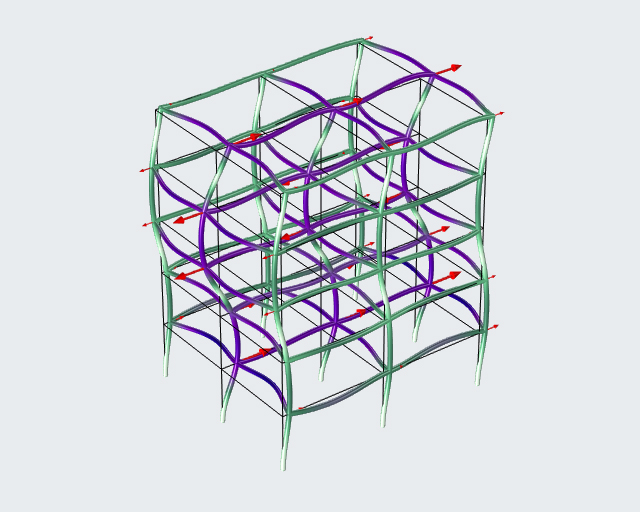

Coupled multi-field simulation

The behavior of wood and wood-based materials is largely dependent on climatic conditions. A variable air humidity, for example, can lead to swelling and shrinkage processes within a joint. In turn, the changing joint geometry influences the moisture and temperature distribution. Through the coupling of physical parameters in COMSOL Multiphysics, we are able to depict such interactions with a reasonable outlay. The consideration of fluid-mechanical problems is also possible. Furthermore, we can expand our multi-field models through user-defined formulations on a needs-oriented basis.

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research