At the HOFZET®, the application-oriented development and production of innovative, technical textiles using the latest weaving technology forms a focus of the applied research. The finished fabrics can be used, for example, as semi-finished products for a composite material or for other technical textile applications. The single or multi-layer fabrics can be applied in thermoset and thermoplastic semi-finished products and components.

Functionalized technical textiles

Research focus

Crucial for this is that not only hybrid structures made from differing, conventional high-performance fibers such as carbon or glass fibers can be produced, but that requirement-meeting combinations with natural fibers and bio-based synthetic fibers can also be created. The benefits of bio-based materials in combination with conventional reinforcing fibers are thereby specifically utilized. The production of technical hybrid textiles with variable biogenic content by means of weaving technology enables the cost-effective manufacture of components with application-oriented properties which include, in particular, outstanding mechanical and acoustic properties as well as very good crash behavior. A further very positive effect is that through the application of bio-based materials, fibers and/or polymers, the costs can be significantly reduced in some areas and the CO2 balance is considerably more positive.

Manufacture of hybrid, textile semifinished products

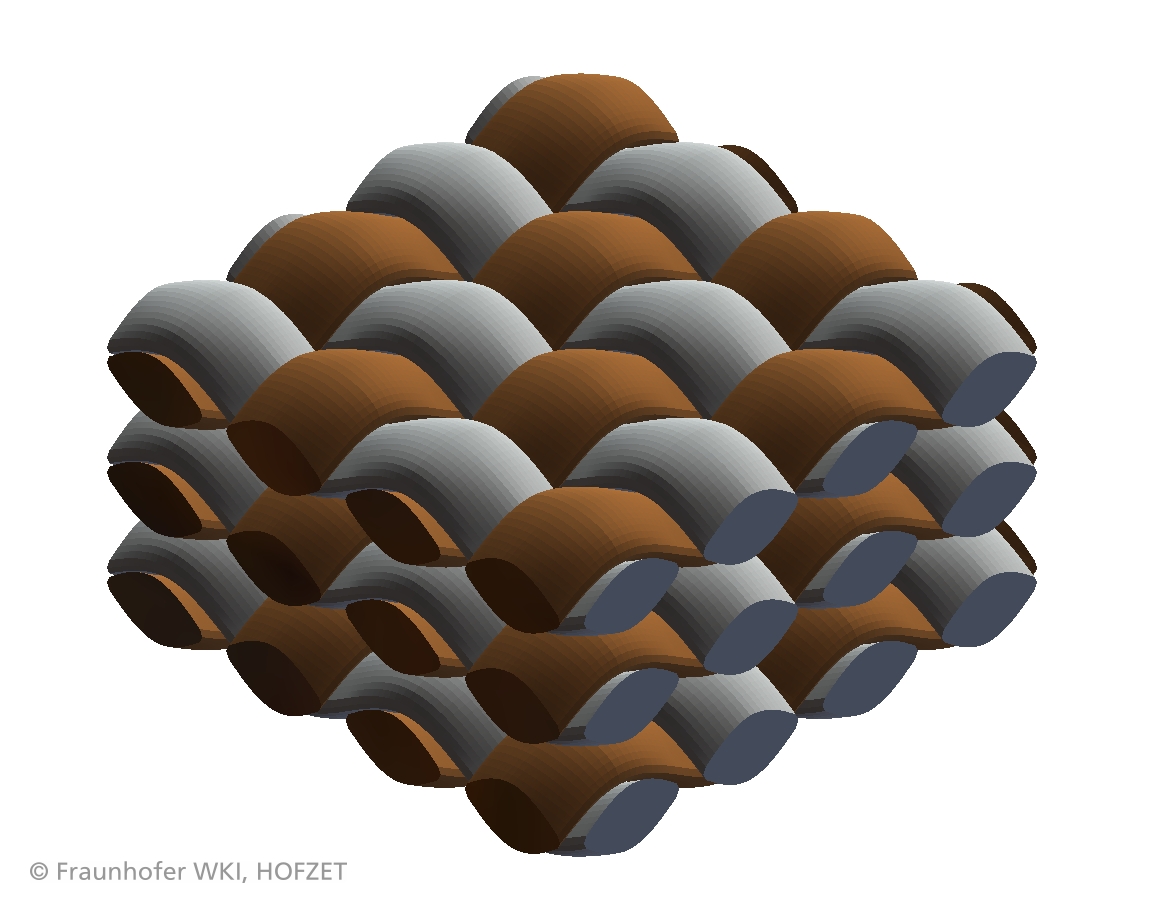

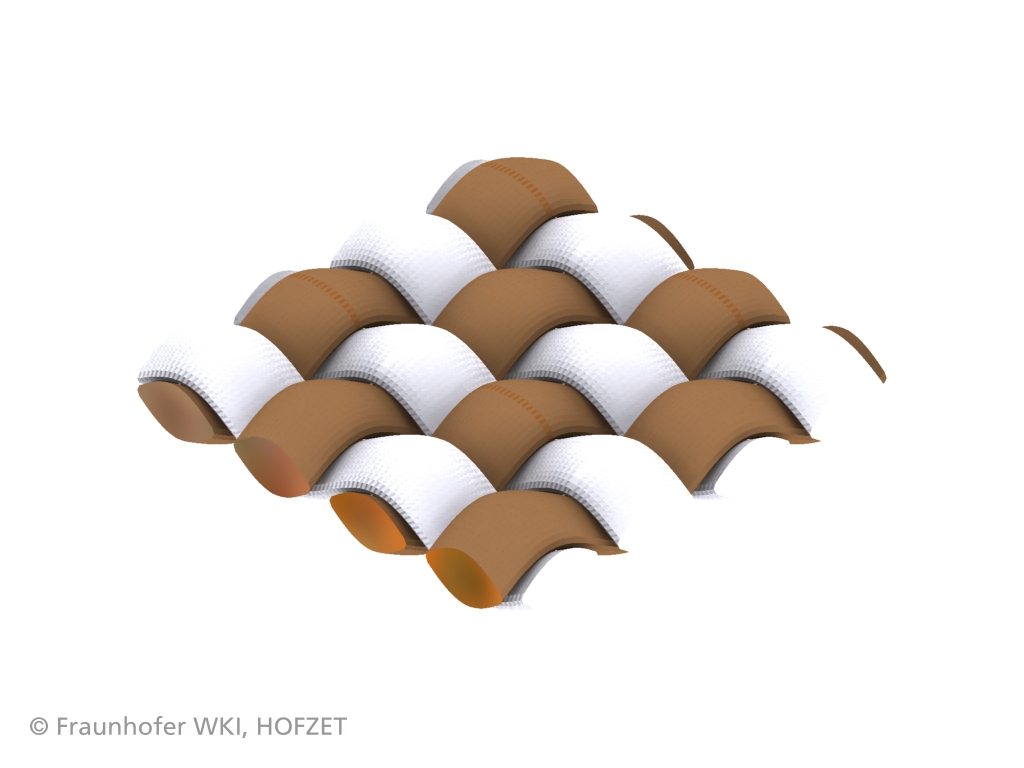

By means of a double-rapier weaving machine with Jacquard attachment from the company Van de Wiele, various fabric structures can be process-adapted manufactured which are each composed of different yarn, filament or roving types. Through diverse and application-oriented combinations of materials, bond variants and fabric constructions, hybrid textile semi-finished products can be produced. With regard to a subsequent processing into composite materials, it is possible to provide the fabric with a thermoplastic matrix yarn. Using this manufacturing technology, an outstanding impregnability, easy handling and a reduction in material consumption and process steps is achieved. In addition to the production of twodimensional hybrid tissues, this technology also enables, amongst other possibilities, three-dimensional and near-net shape fabric constructions. The diverse material selection, together with the advanced technical possibilities of the double-rapier weaving machine, offers a strong flexibility with respect to the mechanical component and performance characteristics of the manufactured semi-finished products, such as an application-specific control of the mechanical, acoustic and optical properties, as well as a reduction of the costs. Furthermore, conductive yarns or wires, which serve as sensors or conducting paths, can be directly integrated into the fabric.

Technical data

- Double rapier

- Jacquard attachment

- Realization of weave widths of up to 50 cm

- Creel for 3456 spools

Production possibilities for technical fabrics

- Two-dimensional fabrics

- Spacer fabrics (spacings up to 40 mm)

- Integration of matrix yarns in textile semifinished products

- Multi-layer fabrics

- Hybrid fabrics

- Function integration

- Load path-appropriate manufacture ofhybrid composites

Expertize

- Development of application-specific textile semi-finished products from hybrid material systems

- Provision of cost-optimized, sustainable high-performance composite materials with the highest possible biogenic proportion

- Combination of bioplastic, natural, glass, carbon and synthetic polymer fibers

- Sustainability, recyclability

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research