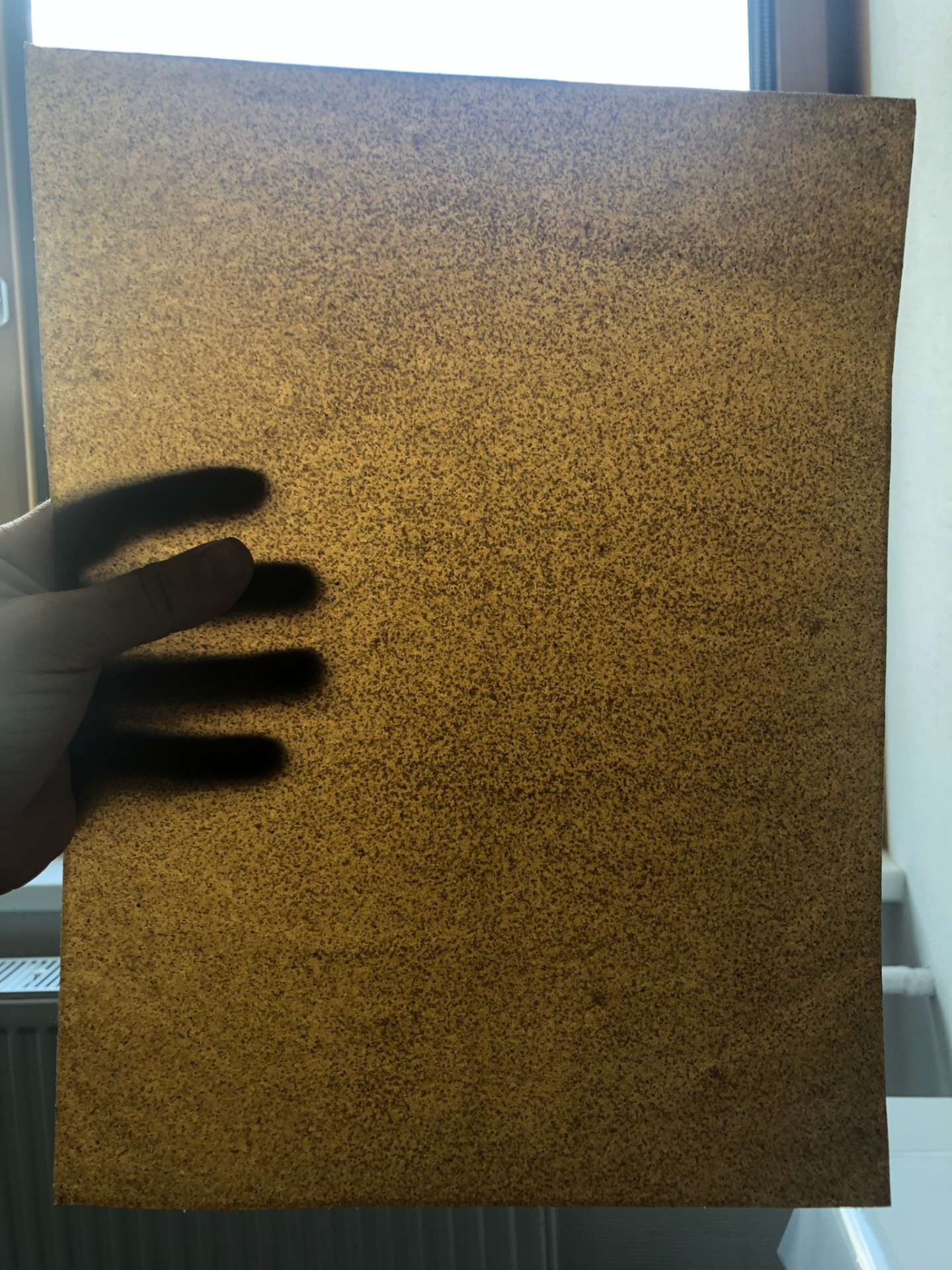

Compostable Single-Use Tableware made from beet pulp

To protect the environment, especially the ocean, many single-use plastic products are banned in the EU. But single-use products made from unmodified natural polymers are allowed. With this in mind, researchers at the Fraunhofer WKI have teamed up with partners to develop compostable single-use tableware based on local agricultural residue from sugar production.

Many single-use plastic products have been banned in the EU since July 3, 2021, so they can no longer be produced or marketed. However, ecofriendlier reusable solu-tions are not a feasible alternative for all areas of application. There is a lack of solutions for functional, environmentally friendly single-use items for trade shows, festivals and other events, for example. According to the EU Single-Use Plastics Directive (SUPD), the only single-use products that have been allowed since 2021 are those made from unmodified polymers that occur naturally in the environment. As a sustainable alternative, researchers from Fraunhofer WKI are working with the Institute of Biotechnology at RWTH Aachen University and Pfeifer & Langen GmbH & Co. KG in the EBRA project (see below) to develop compounds and polymer films based on regionally available plant-based residue from food production, which can be further processed into items such as plates and utensils.

Strengthening regional markets

“Agricultural waste streams such as sugar beet pulp, combined with natural polymers like cornstarch and pectin from beets, have potential for use as raw materials for compostable tableware and utensils,” says Arne Schirp, a research scientist at Fraunhofer WKI in Braunschweig. Beet pulp is especially suitable for further use, since German sugar manufacturers already produce it in the seven-figure metric ton range during beet harvesting. The pulp could be processed into compounds directly on site, keeping transportation routes short, lowering CO2 emissions and strengthening regional markets.

Water and glycerin are added to the mixture of beet pulp, starch and pectin as plasticizers. The project partners were commissioned to perform an ecotoxicological evaluation, in which they demonstrated that the substrate produced in this way is safe to use in contact with food.

Mechanically stable, water-resistant polymer films thanks to bio-based coatings

The materials have various criteria to meet. First, they must be both biodegradable and suitable for home composting, meaning that they can be disposed of in a home compost bin or in municipal green bins. In tests performed for guidance purposes, the researchers proved that the materials decompose faster than conventional paper plates over a 12-week period. They also feature greater stability than the reference material. Another requirement is that it must be possible to use existing equipment to produce the compounds and films and shape them into single-use tableware. The materials also need to be mechanically stable and water-resistant for contact with greasy foods such as sausage and other oily dishes. The researchers aim to achieve this with bio-based coatings developed by RWTH Aachen University.

“The mixture of ground beet pulp, cornstarch and additives is produced in a com-pounder first and then formed into pellets. The pellets are pressed into a film that is then coated and, as the final step, shaped into plates,” Schirp says, explaining the production process. Because the polymers used for this have low melting points or no melting point at all, little energy input is required to produce new materials from them. The agricultural residue can be upcycled with an eye to sustainability.

Plates have already been produced for use as demonstrators. Materials for single-use utensils, which are to be made using injection molding, are currently in preparation. As their next step, the project partners plan to transition production to an industrial scale and begin marketing the products.

Last modified:

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research