Saccharides with vegetable oils and fats are industrially important renewable resources. The monosaccharide glucose is primarily obtained from corn, potato and wheat starch. From glucose as starting substance the radical polymerizable sugar methacrylate can be synthesized in a two-steps reaction. The sugar methacrylate can be used in the synthesis of novel water-based acrylic dispersions by means of radical emulsions polymerization.

The properties of acrylic dispersions are influenced by the manufacturing process and the recipe. Very fine and relatively soft acrylic dispersions with a low solid content usually lower than 15% and a low viscosity are suitable for wood primers. The majority of acrylic dispersions for interior wood coatings are very fine sized with an average particle size from 50 to 100 nm. They are usually formulated with a high glass transition temperature from 30 to 60°C in order to achieve the desired hardness (see Fig. 2). However, the increasing environmental pollution as a result of solvent emission leads to the substitution of solvent-borne coatings by water-based products.

The thermal behaviour of acrylic dispersions plays a decisive role for the film formation. The glass transition temperature affects strongly the minimum film forming temperature. The sugar methacrylate as polymer exhibits a high glass transition temperature at 164°C. Accordingly to this the sugar methacrylate, as hard monomer, increases the glass transition temperature of the copolymer. The basic properties, such as polarity, hardness and flexibility of the coating, are fixed in the copolymer through the choice of standard monomers. The saccharide containing film formation takes place at room temperature without addition of a coalescing agent. Basically, it is also possible to make it a hydroxy functionalization 2K polyurethane acrylates and thus to cross the additional crosslinking to even higher-quality coating materials.

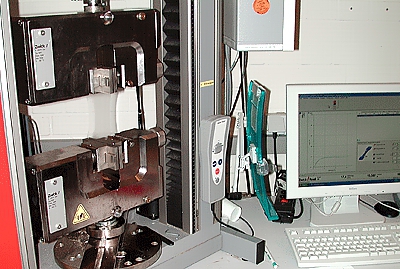

The beech plywood panels coated with a saccharide-containing acrylic dispersion are investigated according to DIN EN ISO 2409. The cross-cut test values of wet adhesion fulfil the normative requirements of wood external coatings. Furthermore the elasticity and the tensile strain of free lacquer films are investigated. Wood is a natural and flexible material. Therefore a suitable wood coating should be able to stand swelling, or other minor deformations of wood without cracking. The lacquer films are stored in the controlled environment and then artificially aged by storage in water. The selected saccharide-containing films provide an elasticity of more than 20%. The selected saccharide-containing films provide an elasticity of more than 20% (see Fig. 3).

The high glass transition temperature of the sugar methacrylate can open ways to develop formaldehyde-free adhesives for wood-based materials. This will require further investigations.

Present results show that the radical polymerizable methacrylate containing glucose forms a technically functioning alternative to synthetic raw materials for the synthesis of acrylic dispersions. It is preferably suitable as a hard monomer for furniture lacquers. The subject of future research is to find out to what extent it is possible to produce formaldehyde-free binders for the wood products industry.

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research