Better planning of road repairs: Asphalt-integrated measurement system could prevent traffic jams

In collaboration with the Hochschule Hannover University of Applied Sciences and Arts, the Magdeburg-Stendal University of Applied Sciences, and the Fraunhofer IFAM, scientists at the Fraunhofer WKI have begun fundamental research into a measurement system which can be used to measure the condition of a road over long distances - at any time, and without damaging the road. The German Federal Ministry of Transport and Digital Infrastructure (BMVI) has enabled and funded the project. Reconstruction measures could consequently be planned better and earlier - ideally for a timeframe outside of vacation periods. Up until now, core tests have been carried out. These cause additional damage to the road to be examined, incur expense, and result in road closures. They can therefore only be performed on a random basis.

The “SenAD” project was funded with a total of 90,000 euros by the German Federal Ministry of Transport and Digital Infrastructure within the framework of the mFUND innovation initiative. In collaboration with partners, the Fraunhofer WKI has demonstrated the fundamental feasibility of a measurement system on the basis of an electrically conductive material that is integrated into a bio-based fabric. This hybrid fabric could be incorporated into the asphalt surface layer in the future. As the asphalt surface layer fatigues over time as a result of the effects of traffic and weathering, changes in the electrical resistance of the sensor material occur in the sensor fabric. The changes in resistance therefore provide information concerning the degradation state of the asphalt surface layer. As a result, remedial measures can be planned better and, above all, more sustainably. If the sensor system is installed in the asphalt layer at specific intervals, it is possible to obtain measurement points across virtually the entire road. Through the use of differing transmission paths, the data can be read out not only without contact, but even externally from a central point, without the need for personnel on site. By utilizing low-cost measurement electronics, the equipping of roads with sensors results in only minor additional costs.

“When damage processes occur in the asphalt, the integrated sensor fabric is affected simultaneously. It is therefore possible to infer the time of failure of the asphalt structure from the fatigue state of the conductive material. The data show the current internal condition of the surface layer. In the long term, this method could replace the destructive tests currently being applied,” explained Christina Haxter, Project Manager at the Fraunhofer WKI.

The carrier fabric in which the sensor technology is integrated is completely bio-based. The fabric development and manufacture was carried out at the Fraunhofer WKI in close cooperation with the Fraunhofer IFAM and the Magdeburg-Stendal University of Applied Sciences. The aim of the fabric development was to design and manufacture a bio-based leno fabric that meets the special requirements of road construction by means of a specifically developed design (grammage, yarn spacing, and displacement resistance). In particular, the largest possible yarn spacing with simultaneously sufficiently high displacement resistance as well as integration of the sensor wires posed a special challenge.

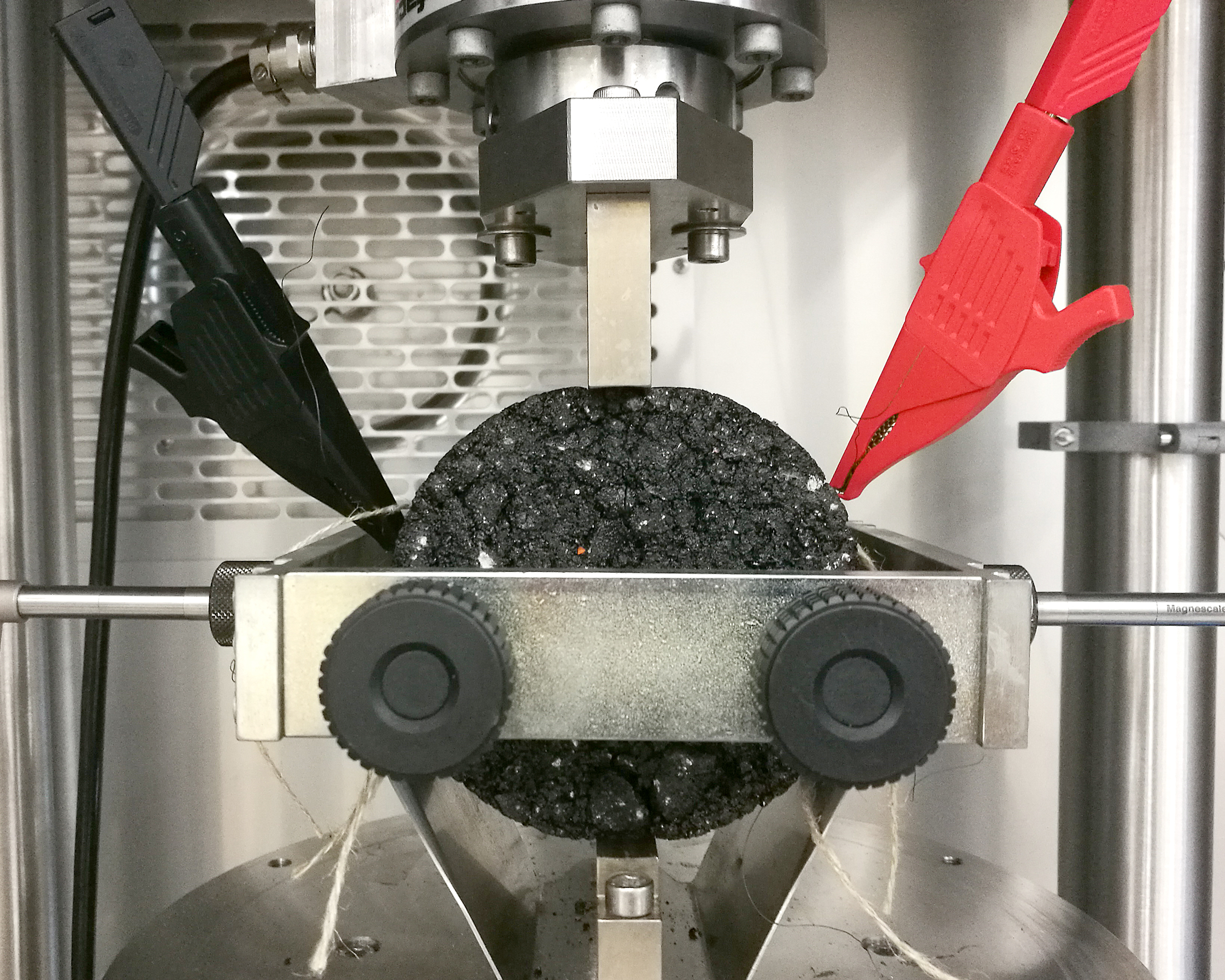

The measuring system was integrated into asphalt test specimens at Magdeburg-Stendal University of Applied Sciences and subjected to mechanical stress. At the same time, researchers at the Fraunhofer IFAM analyzed the sensor technology and captured the data during this mechanical testing.

The Hochschule Hannover University of Applied Sciences and Arts carried out the processing and evaluation of the measurement results using adapted data-analysis software. For the interpretation of future measurements, the correlation between resistance change and degradation of the road was determined. The results from the mechanical testing and sensor analysis were used to calibrate the software and evaluate its predictive accuracy.

The findings can not only simplify planning in road construction but can also form the basis for many other applications. An integrated measurement system can be implemented in diverse further areas of structural and civil engineering. Furthermore, new functions can be integrated into components used in the construction industry. The consortium comprised of the Fraunhofer WKI and IFAM as well as the Universities of Applied Sciences and Arts of Hannover and Magdeburg-Stendal is already in close contact with representatives from industry, who are showing great interest in the innovative research approaches. Further collaborative research into the aforementioned issues has already been initiated.

The BMVI mFUND funding program

Within the framework of the mFUND innovation initiative, the BMVI has been supporting research and development projects related to data-based digital innovations for Mobility 4.0 since 2016. Project funding is supplemented through active professional networking between stakeholders from politics, business, administration and research and the provision of open data on the mCLOUD portal. For more information, please visit www.mfund.de.

The background of the Fraunhofer WKI

Sustainability through the utilization of renewable raw materials has formed the focus at the Fraunhofer WKI for 75 years. The institute, with locations in Braunschweig, Hanover and Wolfsburg, specializes in process engineering, natural-fiber composites, binders and coatings, wood and emission protection, quality assurance of wood products, material and product testing, recycling procedures and the utilization of organic building materials and wood in construction. Virtually all the procedures and materials resulting from the research activities are applied industrially.

Last modified:

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research