#WeKnowWood: Fraunhofer WKI presents ceiling-system module at LIGNA 2023

With the ceiling-system module for the modernization of suspended ceilings in buildings, researchers at the Fraunhofer WKI are demonstrating at LIGNA 2023 an ecological possibility for the renovation of old buildings. With the prefabricated small panels in modular construction, renovations will be easier and faster to carry out in the future.

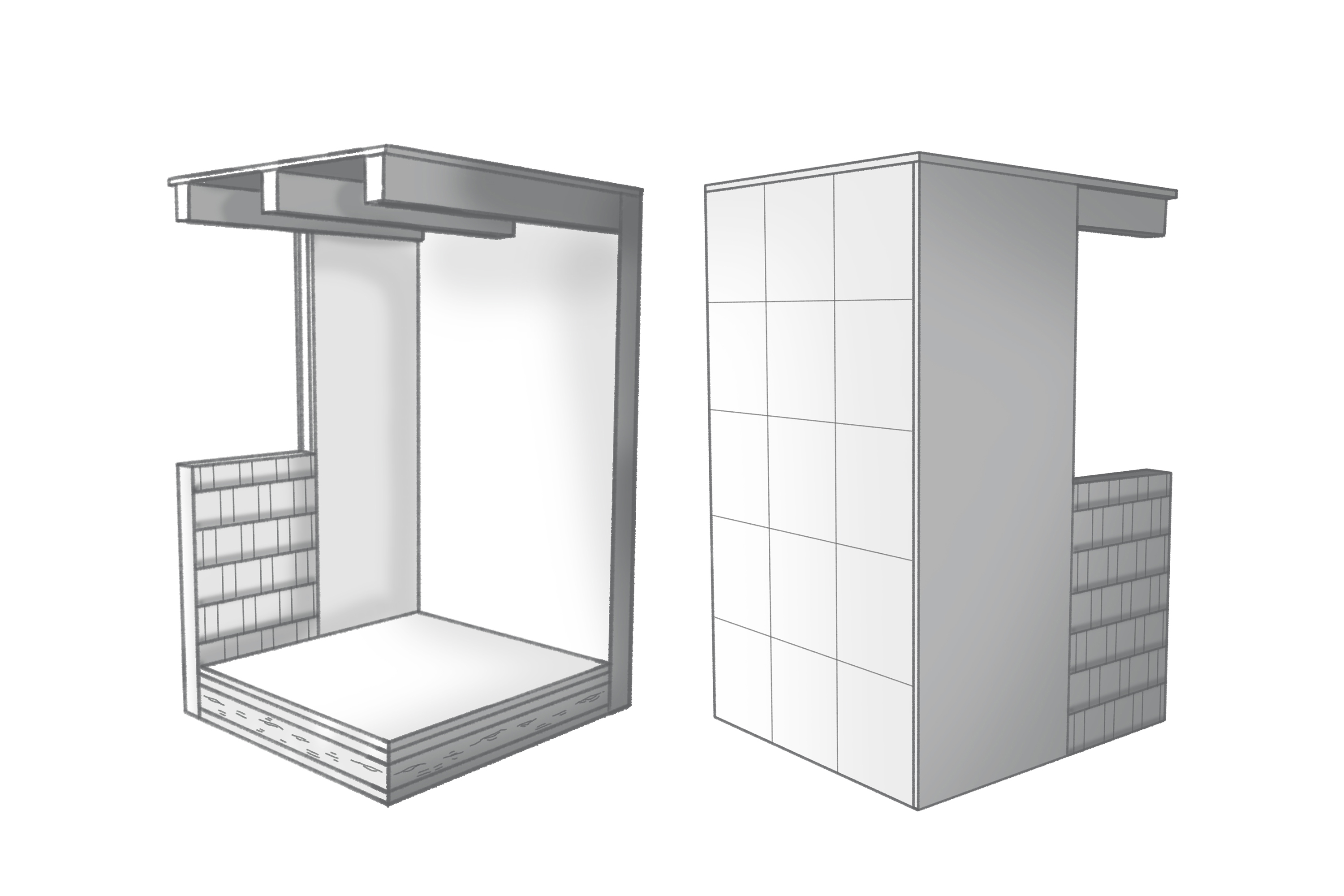

The ceiling-system module forms the floor of the “Multi-material model Wall I Ceiling I Roof”, which is currently on display at LIGNA 2023. The small panels, with a high proportion of renewable raw materials, are intended to replace suspended ceilings in old buildings which have a low load-bearing capacity and which provide poor soundproofing. The area of application is extensive: Of the approximately 9 million old buildings in Germany, around 70 percent have not yet been renovated for energy efficiency. In the research project in collaboration with the Institute of Joining and Welding (IFS) of the Technische Universität Braunschweig, the researchers have developed prefabricated small panels with good sound and heat-insulation properties. Modular wood or wood-concrete elements are used to create a mosaic-like coffered ceiling that should ultimately exhibit a load-bearing capacity comparable to that of steel-reinforced concrete.

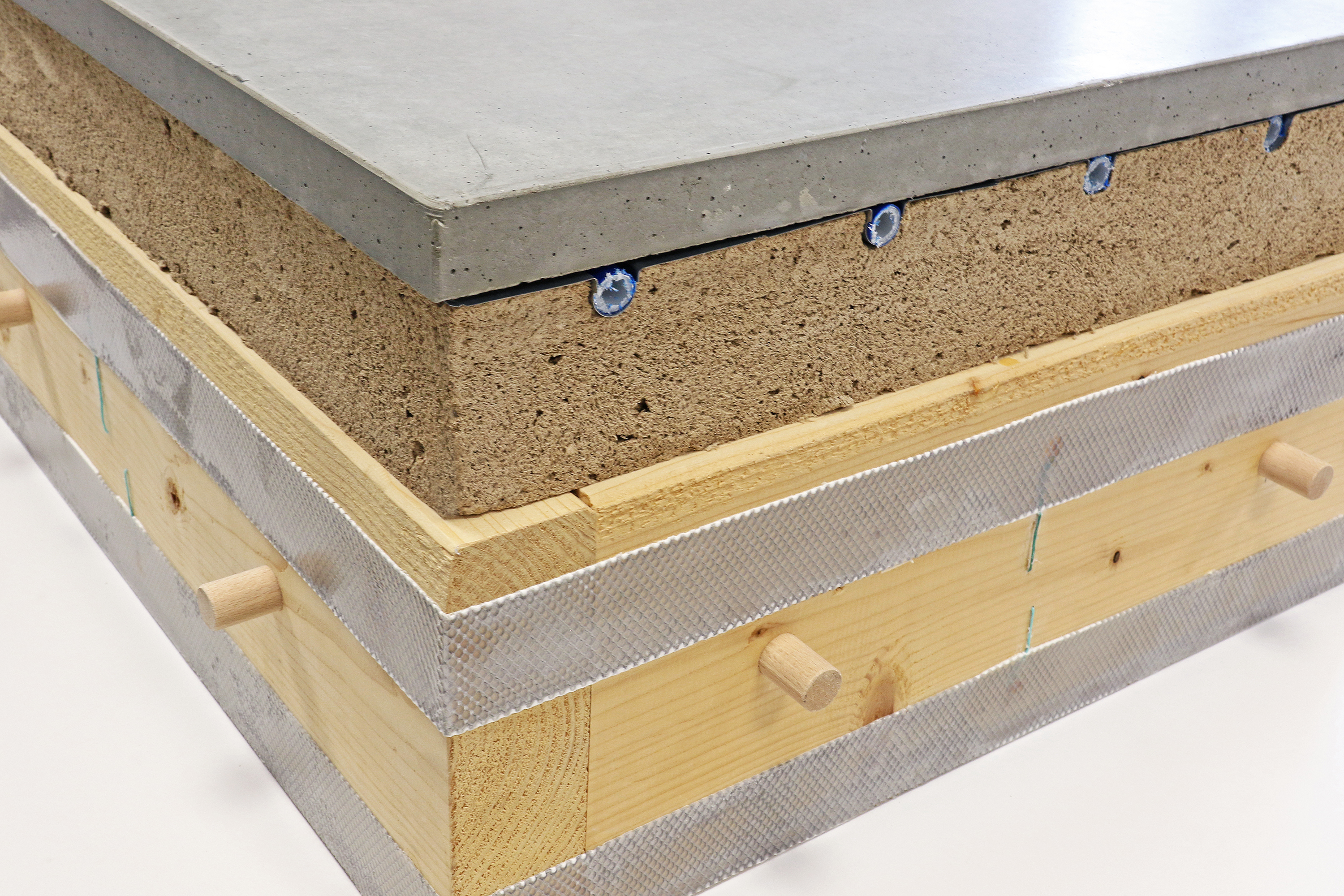

At the Fraunhofer WKI, the researchers selected the wood-based materials and developed OSB boards, amongst other items. The outer box of the ceiling-system module consists of structural solid wood, with a ceiling and a floor each made from OSB boards. “As a result of the use of wood-based materials, the small panels have a low dead weight. This enables the modules to be transported by two people through a stairwell. This is a major advantage for the renovation of old buildings that are often difficult to access,” explained Dr. Steffen Sydow, Project Manager at the Fraunhofer WKI. In order to increase resource efficiency, primarily hardwoods – such as small-diameter beech wood from thinnings – were used in the development of the modules.

The box structure and the push-in connections possess a high inherent rigidity and can therefore be erected in a self-supporting manner. An additional thin textile-reinforced concrete slab furthermore improves the stiffness and footfall sound insulation.

For the sandwich core in the box filling, the wood foam previously developed at the Fraunhofer WKI was used, which simultaneously increases the thermal and acoustic insulation. “The sound absorption provided by the wood foam works so well that the small panels could also be used as acoustic panels to improve room sound,” said Dr. Sydow. The ecological wood foam uses renewable raw materials to replace petrochemical insulation materials such as PU or XPS foams.

At the project partner IFS at the TU Braunschweig, a new bonding technology with conductive rapid-heating adhesive tapes was developed. The adhesive tapes are attached to the module edges during pre-assembly. An electrical contacting system allows the modules to be quickly connected to one another at the construction site. In principle, dismantling after the use phase is also possible using the same method. This offers advantages for recycling. The researchers at the TU Braunschweig have also tested the load-bearing capacity of the ceiling composite –with positive results.

With the ceiling-system module, the renovation and subsequent use of old buildings in times of housing shortage is promoted in an ecological manner. For increased comfort, it is even possible to integrate underfloor heating into the ceiling-system module. In the future, these modules could also be used in industrial buildings or as wall modules for improved acoustics.

Experience us live at LIGNA 2023

The Fraunhofer WKI is demonstrating the “Multi-material model Wall I Ceiling I Roof” at LIGNA 2023. The Fraunhofer WKI will be presenting its innovations in Hall 26, Stand B 78. Co-exhibitor is the International Association for Technical Issues Related to Wood (iVTH).

Further information about the exhibition stand: www.wki.fraunhofer.de/en/ligna-2023

LIGNA is the world’s leading trade fair for tools, machinery and equipment for woodworking and wood processing and will be held in Hanover from 15th to 19th May 2023.

Funding

The German Federal Ministry of Food and Agriculture (BMEL) funded the project via the project management agency Fachagentur Nachwachsende Rohstoffe e. V. (FNR). The project is listed in the FNR funding database (funding codes 22007817 and 22023318).

Last modified:

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research