Fraunhofer WKI develops bio film-formers from lignin for sustainable makeup

In collaboration with Schwan Cosmetics International and Worlée-Chemie, the Fraunhofer WKI has developed high-quality bio-based film-formers on the basis of lignin for use in cosmetic products. The foundation has therefore been laid for high-quality and sustainable makeup products whose quality is in no way inferior to that of conventional products.

A quality feature that is a purchase criterion for cosmetic products is their adhesion to the skin, in particular their water resistance. In order to optimize this, polymer dispersions are utilized. They are predominantly based on film-forming polystyrene acrylate copolymers, acrylate copolymers or polyurethanes (PU). These are usually produced from petrochemical raw materials. Alternative film-formers on the basis of renewable raw materials have, until now, been virtually unavailable or do not exhibit the performance capabilities of petrochemical polymer dispersions.

Researchers at the Fraunhofer WKI, in collaboration with partners Schwan Cosmetics International and Worlée-Chemie, pursued the goal of developing novel film-forming polymer dispersions on the basis of wood components for use in cosmetics. Worlée-Chemie thereby focused on the development of a cellulose-based film-former, and the Fraunhofer WKI utilized lignin as a source of renewable raw material. Schwan Cosmetics International developed makeup formulations using the prototypes, and conducted application and stability tests.

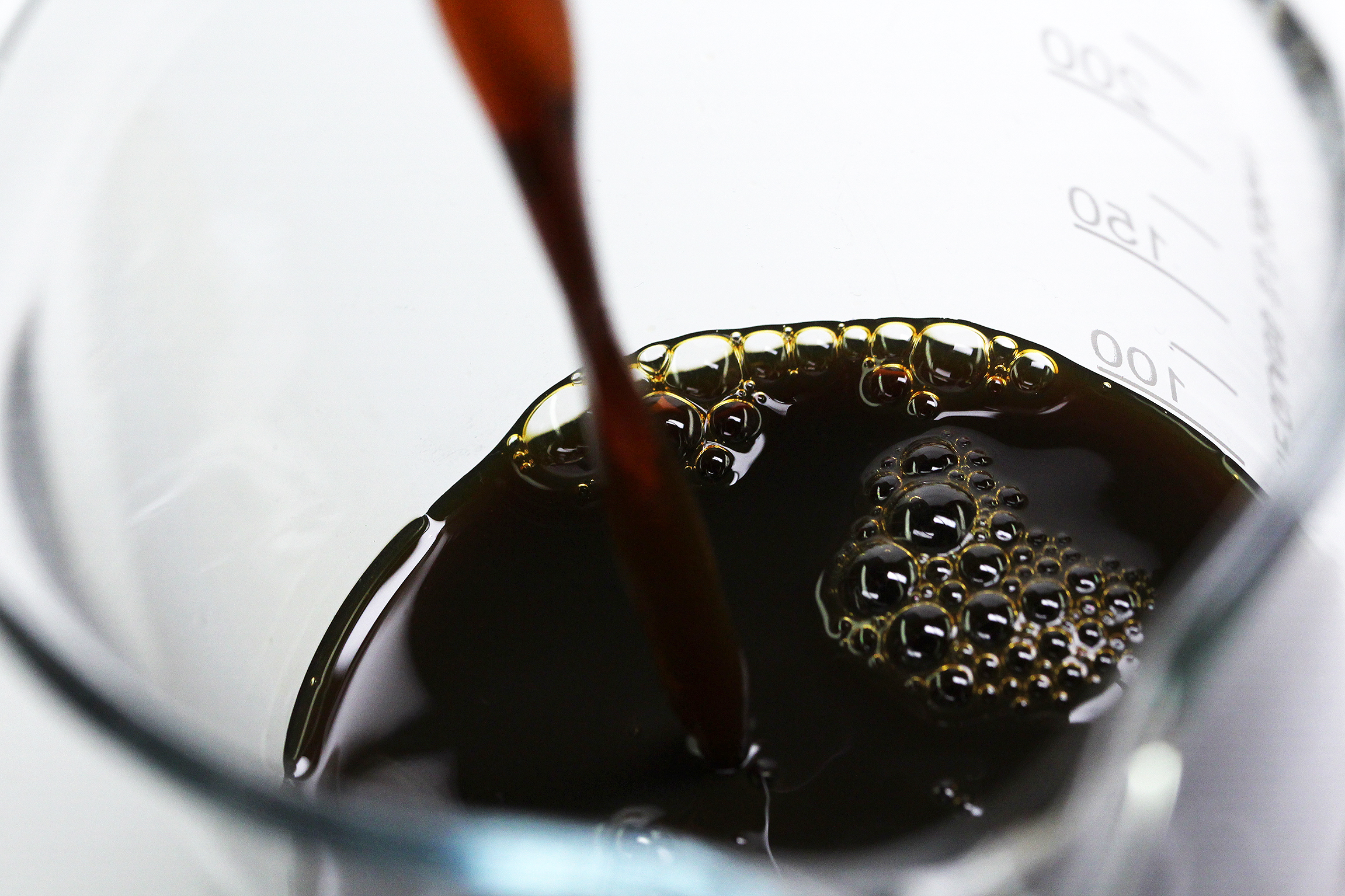

“Within the framework of the project, at the Fraunhofer WKI we addressed the question of whether lignin is suitable as a sustainable component for a bio-based polyurethane film-former. Lignin, a component of trees, is a byproduct of pulp production,” said Dr. Stefan Friebel, Project Manager at the Fraunhofer WKI. Further synthesis building blocks used by the researchers originate from byproducts of sugar production or vegetable oils. The final dispersions have an NOC (natural origin content) of up to 90 percent. The lignin proportion in the polymer is thereby as high as 38 percent. The bio film-formers have a very narrow particle-size distribution, with an average particle size of approx. 100 nm. Film formation takes place at room temperature. The films are very transparent, water-resistant and have a brownish color - due to the lignin.

Worlée-Chemie investigated different synthesis routes for modified celluloses and demonstrated that the cleavage of a hydroxyethyl cellulose and subsequent synthesis with bio-based acrylates results in the creation of a hybrid polymer. This enables very high water resistance to be achieved in eyeliner formulations.

Schwan Cosmetics International was able to demonstrate in various formulations that the novel bio and hybrid polymer dispersions are suitable for makeup products such as eyeliners. Furthermore, application tests verified very good water resistance and very good wearing properties. Stability tests with the formulations and compatibility tests with commonly used raw materials (glycols, preservatives) were successfully carried out in aqueous makeup formulations.

Event information

The project partners will present their results within the framework of presentations at the SEPAWA® CONGRESS 2023 from 25th to 27th October in Berlin.

Further information:

https://sepawa-congress.de/en/poster-expositions-presentations-sepawa-congress/

Last modified:

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research