Renewable raw resources for insulation and other materials: Fraunhofer WKI conducts research for the future

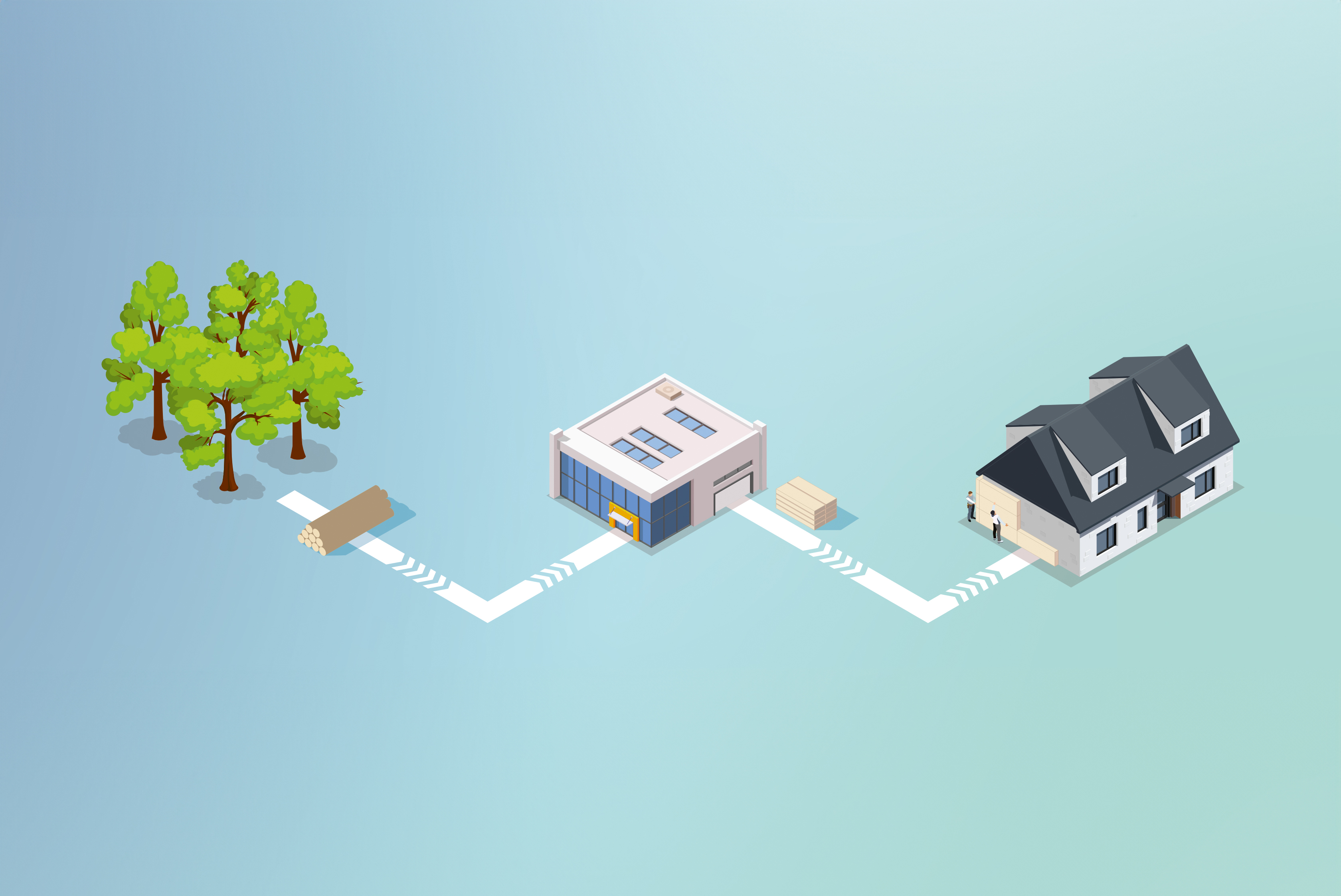

How can finite resources be conserved and dependency on fossil resources reduced? Renewable raw materials are one answer. Researchers at the Fraunhofer WKI are developing new materials and components made from such materials as wood, flax and hemp fibers and fungal mycelium. Together with the Verband Dämmstoffe aus nachwachsenden Rohstoffen e.V. (association for insulation materials made from renewable raw resources, vdnr), the Fraunhofer WKI has been selected to present its expertise in the field of insulation materials at the “Woche der Umwelt” (Week of the Environment) in Berlin on the 4th and 5th of June 2024. The expertise ranges from raw-material extraction, through insulation production and its application in the construction industry, and on to recycling and the utilization of recycled raw materials for second-use products. Scientists will be presenting insulation materials made from plant-based raw resources for applications in the construction sector.

Fossil fuels such as lignite, crude oil and natural gas are important sources of energy. Crude oil, for example, is used in the production of plastics. Finite raw materials such as limestone, gravel and sand are used to produce cement and concrete. The utilization of fossil raw materials is problematic. Firstly, deposits are limited, and secondly, the use and recycling of fossil raw materials produces large quantities of CO2. Renewable raw materials represent an important alternative here.

The Fraunhofer WKI has a long tradition of researching the material utilization of wood. More than 70 years ago, founder and eponym Dr. Wilhelm Klauditz was already looking for solutions to the problems caused by the scarcity of raw wood due to the war and to enable the use of residual and weak wood, for example in the form of particle boards. Today, the researchers are working on a wide range of renewable raw materials and their holistic utilization. In addition to wood, the focus is also on agricultural products, such as flax and hemp fibers or fungi, as well as biorefinery products, such as oils or sugar. A particular focus is formed by the use of plant residues and waste materials. Examples include straw, rice husks, corn cobs or beet pulp, lignin as an industrial by-product, and recycled plant-based raw materials and waste wood.

Plant-based raw materials are not only sustainable, but also have advantageous properties that can be exploited for the production of high-performance and functional biochemical products and biomaterials. For example, vehicle body parts made from natural-fiber-reinforced plastic exhibit good crash-relevant properties. And insulation materials made from natural fibers provide good thermal insulation and have a positive effect on the indoor climate.

Within the scope of a holistic approach, the scientists specifically select raw resources with favorable material properties. Depending on the application objective, these are broken down, modified and further processed using process engineering and/or chemicals. Through clever combinations of raw resources and materials as well as suitable additives, the researchers at the Fraunhofer WKI are able to achieve the best results from renewable raw materials. In in-house laboratories and materials centers, they also develop and test the corresponding manufacturing, shaping and joining processes on a semi-industrial scale. For bio-based chemical products such as adhesives, fire retardants or coatings, they synthesize bespoke binders and develop application-specific formulations. This results in materials, semi-finished products and end products with optimized material and component properties as well as integrated functions - for diverse sectors.

Last modified:

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research