LIGNA 2025:

Bio-based flame-retardant solutions for wood and hybrid materials

At LIGNA 2025, researchers from the Fraunhofer WKI will be demonstrating that bio-based flame-retardant coatings can provide durable fire protection for wooden furniture. A honeycomb-shaped shelf unit with the novel flame-retardant coating, as well as other exhibits, can be seen at LIGNA 2025, Hall 26, Stand B78 from the 26th to the 30th of May 2025 in Hanover.

Bio-based flame-retardant coatings for wood and hybrid materials provide support for environmentally-friendly and sustainable construction methods. They reduce the use of petrochemical raw resources and promote the utilization of renewable materials. At the Fraunhofer WKI, researchers are developing innovative coatings that are formaldehyde-free and reduce the risk of harmful emissions.

With these improved bio-based flame-retardant coatings, strict environmental and fire-safety regulations can also be complied with in indoor areas, thereby opening up new market opportunities for manufacturers. Viewed holistically, bio-based flame-retardant coatings contribute towards a more sustainable and healthier form of construction that corresponds to the needs of modern society.

“InnFla”: Bio-based flame-retardant coatings for furniture and interior woodwork

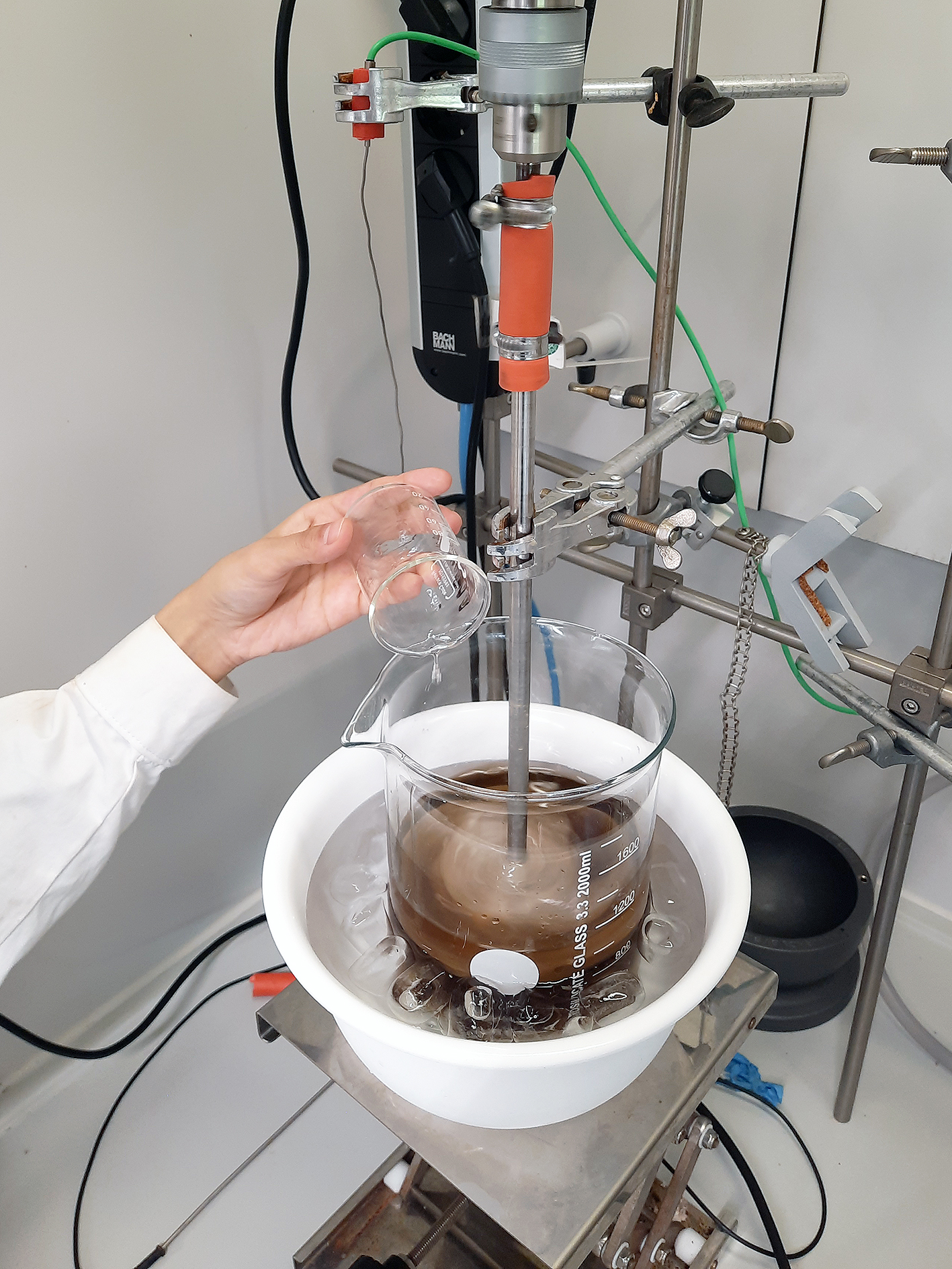

Furniture and building elements made from wood and wood-based materials are becoming increasingly popular. Despite their environmentally-friendly nature, a lack of sustainable flame-retardant solutions for interior wood surfaces has persisted until now. In collaboration with the Braunschweig-based company AURO Pflanzenchemie AG and other partners, the Fraunhofer WKI is therefore developing translucent, formaldehyde-free flame-retardant coatings on the basis of renewable raw materials with a permanent fire-protection effect.

“Traditional flame-retardant coatings are often based on petrochemical binders and salt-based flame retardants. Our innovative approach aims to make wood products “flame-retardant” using bio-based flame-retardant coatings, without the active substances being washed out over time,” explained Claudia Schirp from the Fraunhofer WKI.

The new coatings were tested on solid wood and three-layer boards. They contain at least 50 percent renewable raw materials and are translucent, which means that the wood structure remains visible. As a result, new possibilities are being opened up for furniture and interior design, particularly in schools, theaters and airports. At LIGNA, the researchers will be presenting a shelf unit with honeycomb-shaped compartments that has been treated with the innovative flame-retardant coating.

“ScaleAmP”: Ammonium phytates as the basis for bio-based flame retardants

The “ScaleAmP” research project aims to develop sustainable flame retardants on the basis of plant-derived phytic acid extracted from corn steep liquor. This phytic acid, which is produced in large quantities as a by-product of corn-starch production, is being investigated as a flame-retardant active substance. The focus of the project lies in the development of a cost-effective and commercially viable production process for ammonium phytates. The project is being conducted in cooperation with the Fraunhofer IAP and the companies Cargill Deutschland GmbH and Clariant Plastics & Coatings Deutschland GmbH, and is intended to increase the competitiveness of bio-based flame retardants. This will promote the use of biomaterials and support a bio-based circular economy.

At LIGNA 2025, the value chain from agricultural residues through to flame-retardant biocomposites on the basis of biopolymers and wood will be presented.

“FireSafe-CLT”: Bio-based flame retardants from renewable raw materials for the fire protection of cross-laminated timber

In the construction sector, cross-laminated timber (CLT) has proven to be one of the most versatile wood products: it is used in walls, ceilings and floors and as an element in modular constructions. The main objective of the FireSafe-CLT project is the development of CLT with very good fire and environmental properties. This is to be achieved through the development of bio-based flame retardants from agricultural and wood-processing residues; these retardants are then to be used in adhesives and coatings.

The project results should enable an improved exploitation of the market potential of CLT in timber construction for medium- and high-rise buildings. The project is being conducted in cooperation with the company JOWAT SE and the Technische Universität Braunschweig.

Last modified:

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research