ScaleAmP:

Ammonium phytate on the basis of corn steep liquor as a sustainable flame retardant for WPC and other biomaterials

Buildings, vehicles, electronics and Co.: In many areas, more stringent fire-protection requirements apply. Sustainable biomaterials can fulfill these requirements with, among other things, the help of flame retardants. These are currently predominantly produced from petroleum-based, mineral and other finite raw materials. In collaboration with the Fraunhofer IAP, we are developing and testing flame retardants using a plant-based raw material that accrues in large quantities as a by-product in industry: corn steep liquor. The phytic acid contained therein is to be made usable as a flame-retardant active substance. Using a wood-plastic composite (WPC) as an example, we are able to demonstrate the application potential and flame-retardant properties. The aim is the development of an economical production process for the flame retardant on a technical scale. The project provides a contribution towards improving the competitiveness of bio-based flame retardants and increasing the utilization of biomaterials. As a result, we are supporting the development of a bio-based circular economy using locally available waste materials (bioeconomy).

Every year, around 2.3 million tons of flame retardants are applied worldwide - and the trend is rising. The market research institute Ceresana anticipates an increase in demand, particularly in the construction industry. The currently most important types of flame retardants are primarily based on inorganic salts, phosphorus and nitrogen. As early as 2012, the German government declared phosphorus as a raw material with resource-conservation relevance. Since 2014, the European Commission has classified phosphorus as a critical raw material.

With a view to climate protection, finite resources and the environmental compatibility of raw-material extraction, flame retardants made from renewable raw materials are increasingly becoming the focus of attention. A large number of bio-based substances are fundamentally suitable for this purpose. What they all have in common is that they are generally not used on their own, but are combined or functionalized with a second component in order to achieve sufficient performance. The interplay between guaranteed availability, processability, effectiveness as a flame retardant and price is decisive for the potential for large-scale application. Compared to petroleum-based or mineral-based raw materials, bio-based raw materials are often more expensive or are not yet available in sufficient quantities.

This is where the current research project “ScaleAmP” comes into play. It is being conducted in cooperation between the Fraunhofer WKI and the Fraunhofer IAP and builds upon preliminary work carried out by the two research institutes.

Effective flame retardant on the basis of plant-based phytic acid

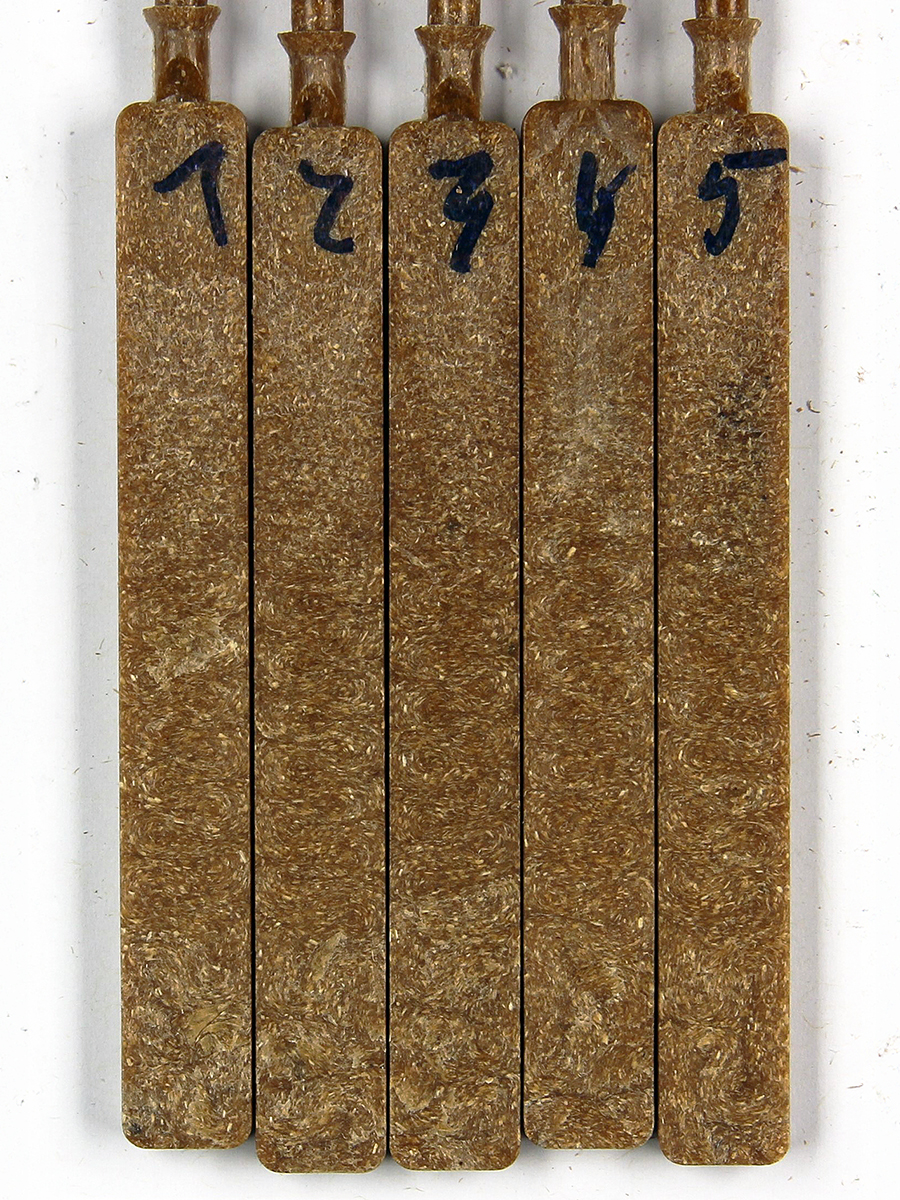

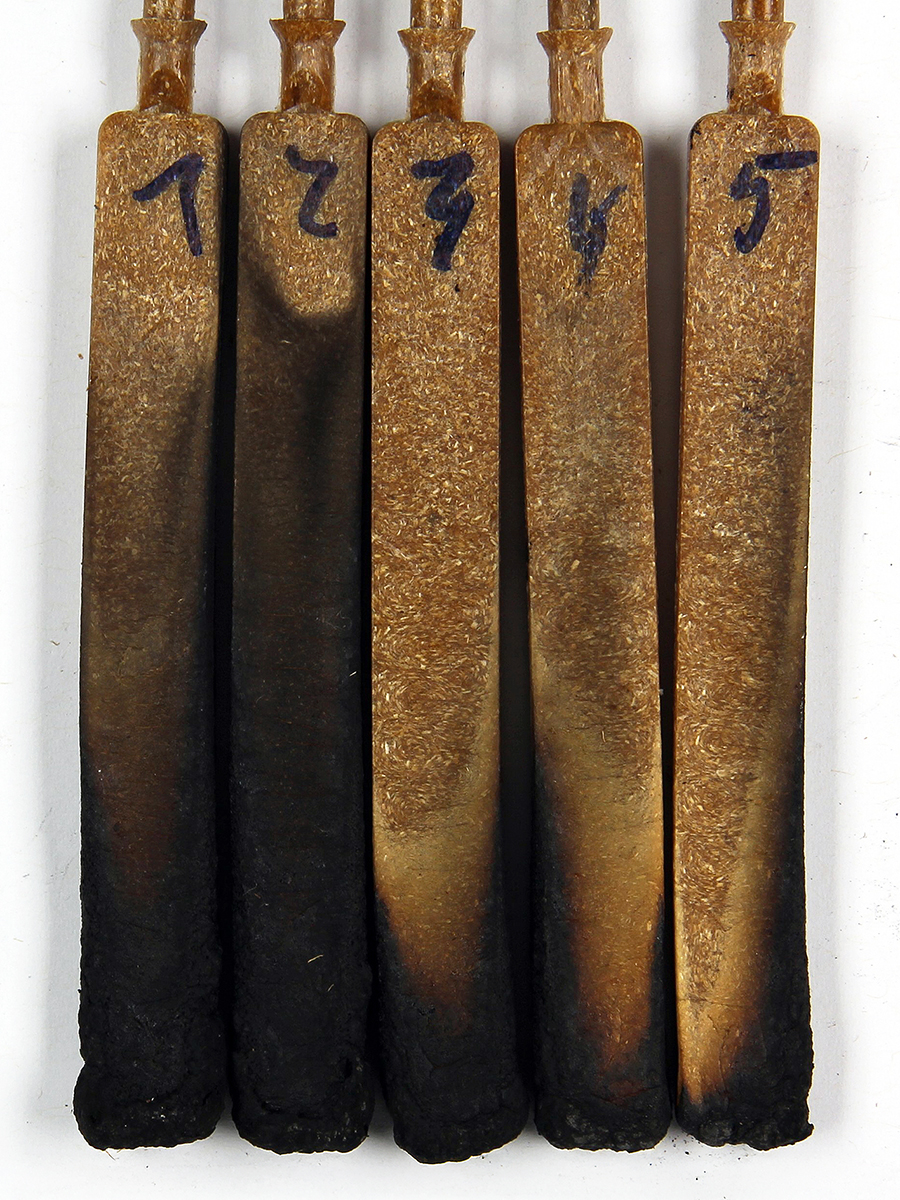

Phytic acid acts as a phosphorus store in plant seeds and is present in large quantities in corn (maize) and soya, for example, as well as in rice, wheat and rye bran. In preliminary work at the Fraunhofer WKI, we have already been able to show that phytic acid, in the form of ammonium phytates, has considerable potential as a flame retardant. There is, however, a need to improve the physical properties. For ease of handling and dosing, the form of a crystalline solid is being targeted. As a model system for the evaluation of the processing and flame-retardant properties, we will compound and comprehensively characterize a wood-plastic composite (WPC) with the developed flame retardants.

Sustainable extraction of phytic acid

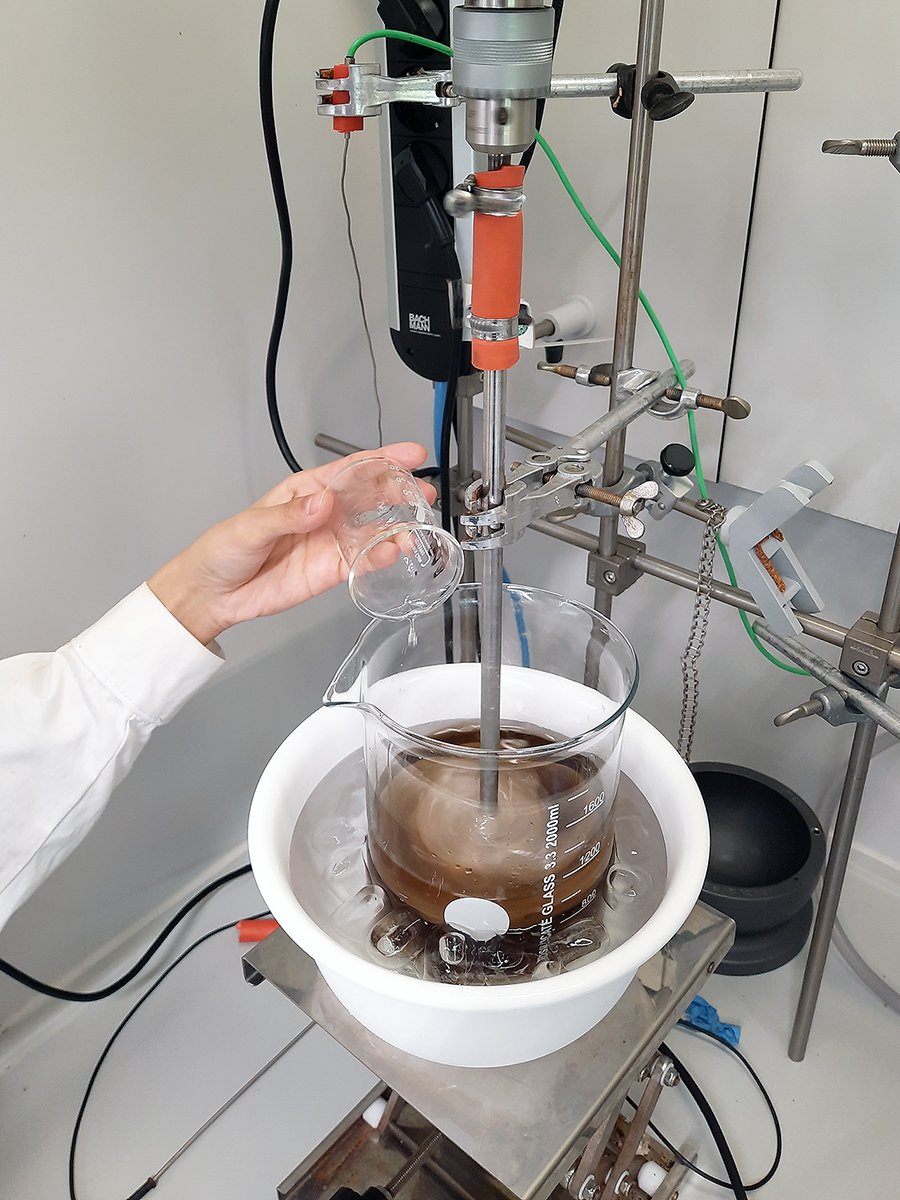

Commercially available phytic acid is currently primarily extracted from rice bran in Asia. The project aims to exploit a European source: corn steep liquor. This accrues in large quantities as a by-product of the industrial production of maize starch. This is due to the fact that an essential pre-swelling process takes place prior to the wet milling of the maize kernels, in which virtually all the water-soluble components, including phytic acid, are extracted from the kernels in several stages. In preliminary work, researchers at the Fraunhofer IAP have already succeeded in isolating phytate salts from corn steep liquor. These are poorly water-soluble compounds that are relatively easily separable. The challenge is therefore to develop an efficient purification procedure for the highly water-soluble ammonium phytates by means of cost-effective process steps and basic chemicals.

Last modified:

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research