LIGNA 2025:

Fraunhofer WKI and TU Braunschweig conduct collaborative research for the future of construction

At LIGNA 2025, the Fraunhofer WKI and the Institute of Building Construction and Timber Structures from the Technische Universität Braunschweig will be presenting groundbreaking approaches for a resource-conserving and climate-friendly construction industry. The trade-fair presentation in Hall 11, Stand F85, will showcase activities in research and teaching revolving around the topic of building with wood and other renewable raw materials: from natural-fiber insulation materials, through timber-concrete composite systems, and on to recycling management.

The construction industry is one of the most resource-intensive sectors, with concrete and steel in particular consuming enormous quantities of raw materials and generating CO2 emissions. In order to reduce the ecological footprint, researchers are turning to wood and renewable raw materials. Even these, however, are not infinitely available. As a result, the need for effective recycling solutions is increasing.

Researchers at the TU Braunschweig and the Fraunhofer WKI are integrating recyclability from the material-development stage onwards and are developing custom-fit processes for the reutilization and recycling of existing products. The aim is to make raw materials usable multiple times and reduce the demand for new resources.

The partners from the Institute of Building Construction and Timber Structures at the TU Braunschweig and the Fraunhofer WKI are working in collaboration on, among other things, such sustainable solutions for the construction industry at the “Center for Light and Environmentally-Friendly Structures ZELUBA®” in Braunschweig. At LIGNA 2025, the cooperation partners will be presenting solution approaches with which the construction industry can both save CO2 emissions and improve the recyclability of raw materials.

“Sus4IChile“: Insulation materials from plant residues for Chile

Researchers at the Fraunhofer WKI have worked with partners in Chile to develop insulation materials from plant residues. Largely unused plant “waste” from the Chilean agricultural, forestry and timber industries can now be put to good use. The utilization of insulation materials made from local raw materials contributes towards improving the environmental balance of the construction sector in Chile and opens up new, previously untapped value-creation opportunities.

Insulation materials made from renewable raw materials are still largely unknown in Chile. The preferred insulation material there is expanded polystyrene, a petroleum-based product. The collaborative project therefore also served to increase the proportion of renewable raw materials in the Chilean construction sector and, consequently, to conserve petroleum-based resources.

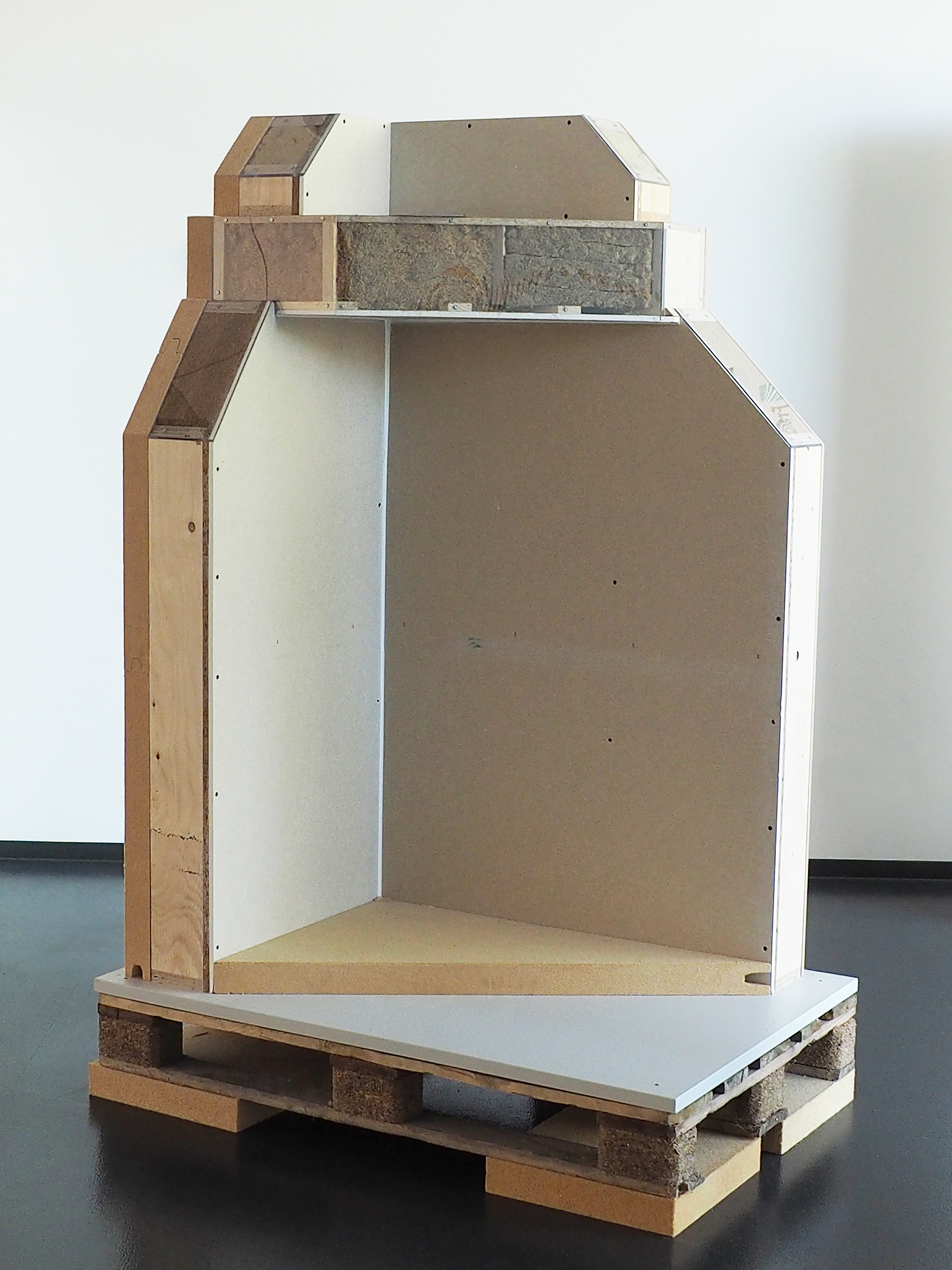

At LIGNA 2025, a demonstrator will be on display that replicates a wall structure. It incorporates wood-based materials and insulation materials made from various renewable raw resources, some of which are second-use products or secondary raw materials. This application example demonstrates the possible uses, particularly in timber frame construction.

“Holztafel 2.0” and “Recycling for Reuse”: Circular economy in timber construction

With the two projects “Holztafel 2.0” and “Recycling for Reuse”, the Fraunhofer WKI and the TU Braunschweig, in collaboration with project partners from industry, are conducting research into how pollutants and impurities can be identified and separated from the dismantled materials. Timber frame construction is a resource-efficient construction method; however, the material mix of metallic, organic and mineral components makes it difficult to cleanly separate by type.

Researchers from the Fraunhofer WKI, the TU Braunschweig, Ruhr University Bochum and four practice partners are working on the development of wooden panels that are easier to recycle. The aim is to recover raw materials and to present a number of demonstrators for “Design for Recycling”. Before old wooden beams can be reutilized, they must be cleaned of harmful substances and metal residues as efficiently as possible. Furthermore, sorting criteria must be developed in order to ensure that the strength and stiffness properties can be maintained for the next 100 years.

The partners are developing mechanical processes for the removal of foreign bodies and wood preservatives as well as classification rules for the reutilization of the material. At LIGNA, waste-wood beams in various stages of processing will be on display to illustrate not only the challenges involved in preparing the wood but also the good material quality beneath the surface.

“LeiWind”: Guidelines for multi-story timber buildings

How do wind loads, which occur as external dynamic effects, influence the usability of multi-story timber buildings? Researchers from the Fraunhofer WKI and the TU Braunschweig are collaborating in order to investigate this question and to develop guidelines for the construction of tall timber buildings. The guidelines encompass vibration studies, numerical analyses such as modal analysis, computational fluid dynamics (CFD,) and fluid-structure interaction. Furthermore, two representative tall timber structures are being evaluated: a solid timber structure and a timber-concrete hybrid structure with different heights.

In addition to examining the components and connections in multi-story timber structures for the development of the guideline, the researchers will also investigate the location of bracing elements, the types of materials (cross-laminated timber and concrete core) for shear walls, and the location of the core. The results of the project will provide a significant contribution towards improving the safety of sustainable structures in terms of their susceptibility to vibration and serviceability in the planning and realization of timber buildings. A film documenting the current status of the research will be shown at LIGNA.

Last modified:

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research