Petrochemical and mineral building materials are currently used in large quantities, although there are currently hardly any viable concepts for material recycling after the end of a building's useful life. When a building is demolished, this results in building rubble that has to be disposed of at great expense. The mineral and fossil resources used in the production of building materials are practically irretrievably consumed. In addition, the production of cementitious building materials and the combustion of petrochemical building materials release enormous amounts of previously bound CO2.

Building materials made of wood and other renewable raw materials, on the other hand, have immense advantages. Here it is possible to establish a sustainable raw material and CO2 cycle. When renewable raw materials are used, CO2 is removed from the atmosphere and bound in the building materials. After a building has reached the end of its useful life, the building materials can be used as raw materials for other products such as consumer goods. At the end of a long and stepwise chain of recyclable materials (cascade use), the materials can finally be burned and thus used to generate energy (thermal utilisation). New raw materials grow back over the entire use phase - ideally more than is used for the products.

There are many possibilities for the cascading use of building materials from renewable raw materials which are far from exhausted. In addition, building materials are also particularly suitable for the use of vegetable waste products, which have so far often only been used thermally or in the form of compost.

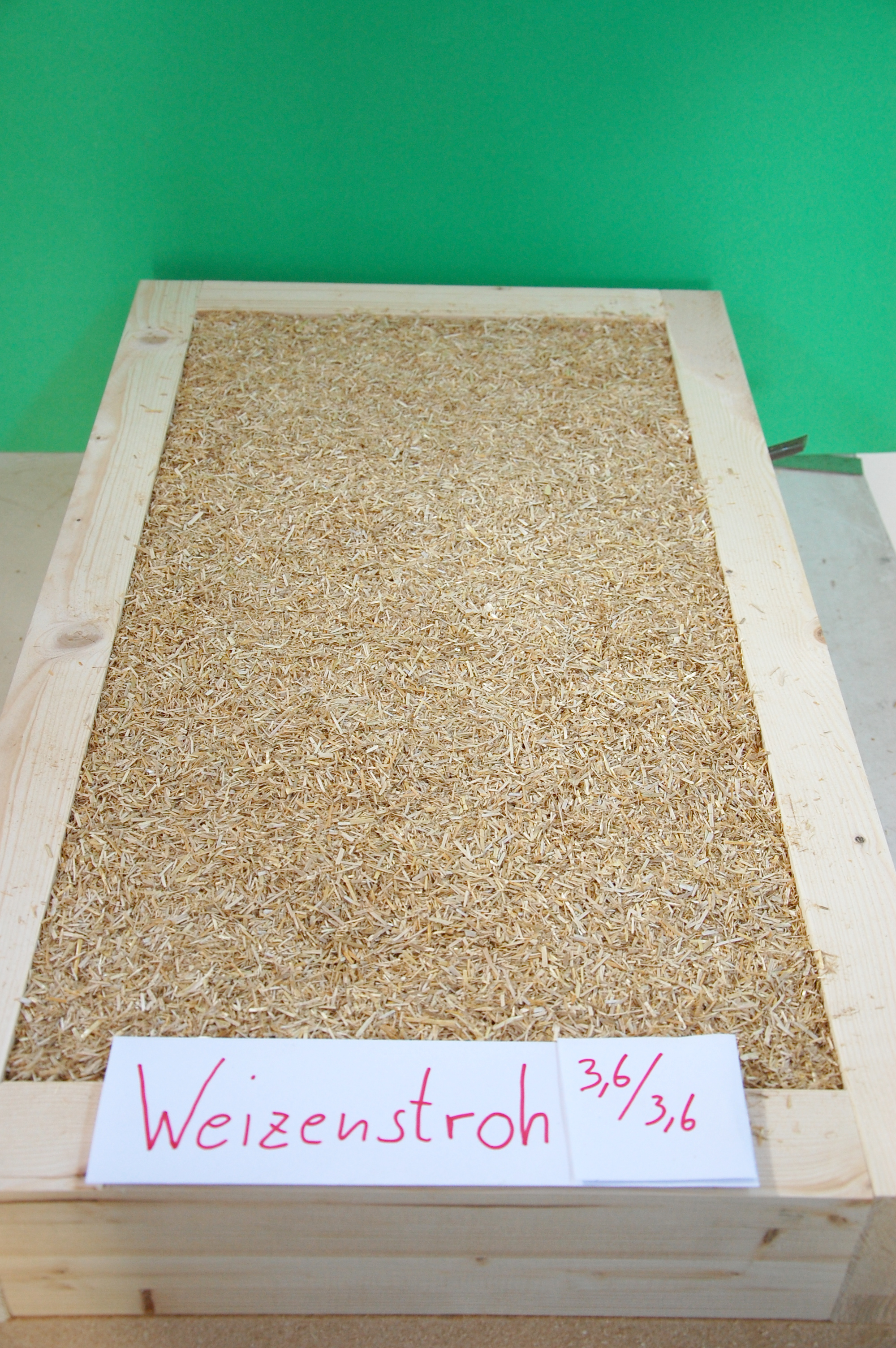

In this project we will develop three different types of insulation made of renewable raw materials for the Chilean market, which cover the typical installation types in residential construction:

- Flameproof insulation board (examples: External wall insulation in thermal insulation composite system, basement ceiling insulation, rafter insulation)

- Flexible insulating mat (examples: Insulation between rafters, floor slab insulation, insulation of ventilated facades)

- Blow-in insulation (for the insulation of structural cavities)

The remarkable aspect: We will design all three insulation materials in such a way that they can be produced from vegetable waste generated in the Chilean agriculture, forestry or timber industry. After mining, forestry in Chile is the second largest export sector. This is not least due to the huge monocultures of exotic plants such as pine and eucalyptus, for which large areas of natural forest have been cleared since the 1970s. To date, there are about 2.3 million hectares of fast-growing plantations in Chile (17 percent of the total forest area). Problems such as soil erosion, a lack of biodiversity and an imbalance in the ecosystem are leading to a return to the country's natural resources.

With our project we are opening up opportunities to use indigenous wood species and agricultural residues in particular. In this way we contribute to renaturation and sustainable forest management in Chile. Insulating materials made from renewable raw materials are largely unknown in Chile. The preferred insulating material there is expanded polystyrene, a petroleum-based product. Our project thus also serves to increase the proportion of renewable raw materials in Chilean construction and thus improve the environmental balance.

The overriding goal is the development of a wooden element that consists entirely of indigenous, renewable raw materials and meets the high quality requirements. Due to the intensified earthquake situation in Chile there are special requirements on the structural stability of buildings. There are also standards for noise and fire protection that must be complied with. The energy performance of residential buildings is not yet a mandatory criterion in Chile, and only a few buildings have been upgraded. However, due to Agenda 2030 and growing awareness of sustainable and energy-efficient construction, thermal insulation is often already being installed in new buildings.

Residual or waste materials from agricultural plants have so far mainly been used as blow-in insulating material in residential construction. Our approach is to also use the residual and waste materials as material mixtures to improve the structural-physical properties of panel or mat materials or as independent materials. This not only enables CO2 savings to be achieved, but is also expected to reduce construction costs for sustainable buildings. The optimization of insulating materials made from renewable raw materials could also open up new economic sectors in Chile.

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research