FireSafe-CLT:

Bio-based flame retardants from renewable raw materials for the fire protection of cross-laminated timber

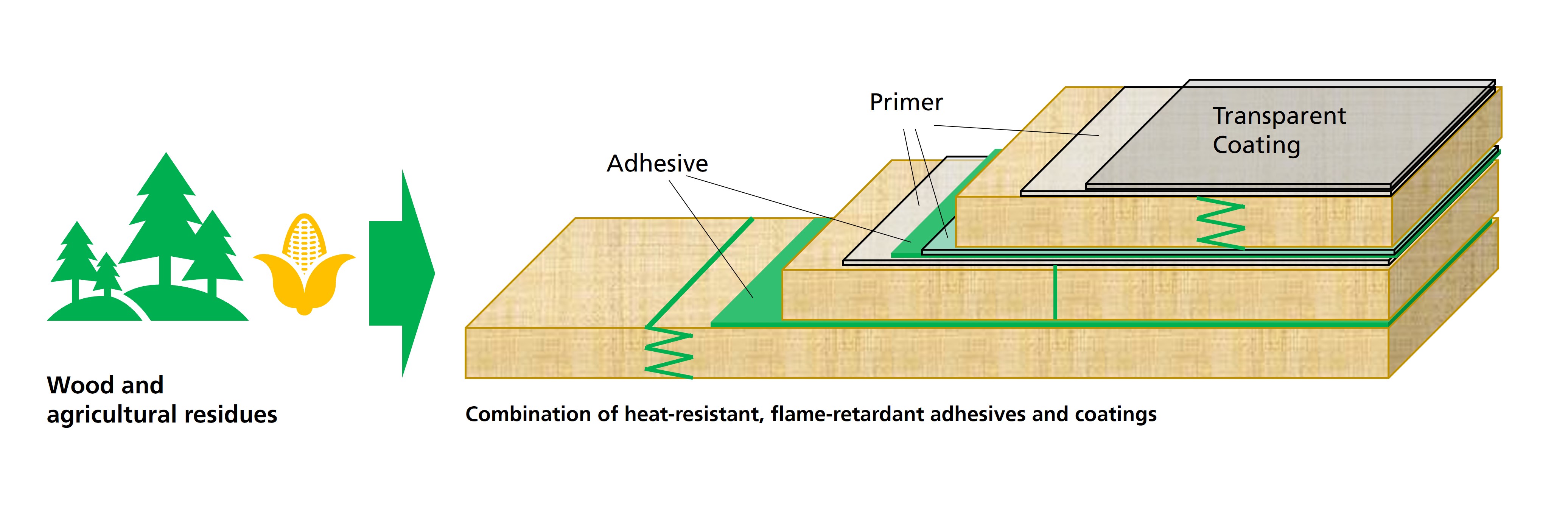

Cross-laminated timber has established itself within the construction industry as a versatile wood product. It is used in load-bearing and non-load-bearing components such as walls, ceilings and floors. In collaboration with researchers from the TU Braunschweig and industrial partners, we are developing cross-laminated timber with very good fire and environmental properties. We intend to achieve this through the development of bio-based flame retardants using residues from agriculture and wood processing. These are to be incorporated into adhesive systems and coatings for cross-laminated timber elements. The project results should enable an improved exploitation of the market potential of cross-laminated timber in timber construction for medium- and high-rise buildings.

Cross-laminated timber (CLT) is a solid wood-based panel comprised of several layers of boards glued perpendicular to one another. It enables timber constructions with high structural strength, load-bearing capacity, dimensional stability and rigidity. Multi-story buildings through to high-rise buildings can be realized with the aid of cross-laminated timber - as a climate-friendly, resource-conserving and cost-efficient alternative to non-renewable construction materials such as concrete, steel or masonry.

As a result of its bulkiness, however, the utilization of cross-laminated timber has a significant influence on the fire load of a building. A distinction must be made here between fire behavior (EN 13501-1) and fire-resistance behavior (EN 13501-2).

Fire behavior is of particular importance in the initial phase of a fire. It refers to the flammability and combustibility of a product and is strongly influenced by the surface properties of the product.

Fire resistance, in contrast, becomes important in the case of load-bearing structural elements (walls, ceilings, floors) once a fire has fully developed. The utilized adhesives must exhibit high heat resistance in order to avoid a delamination of the cross-laminated timber lamellas. The risk of delamination is strongly dependent on the type of adhesive used: Whilst adhesives on the basis of melamine resin formaldehyde (MUF) exhibit high heat resistance, adhesives on the basis of polyurethane (PUR) are susceptible to failure of the adhesive joints at high temperatures. MUF adhesives are, however, increasingly being viewed critically on account of their potential health risk. For this reason, the further development should be focused on PUR adhesives.

Within the framework of the “FireSafe-CLT” project, we are developing a sustainable solution on the basis of renewable raw materials for adhesives and coatings in order to optimize both the fire behavior and the fire resistance of cross-laminated timber.

Last modified:

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research