#WeKnowWood: Researchers from the Fraunhofer WKI present a wall with beech-wood-fiber thermal-insulation bricks at LIGNA 2023

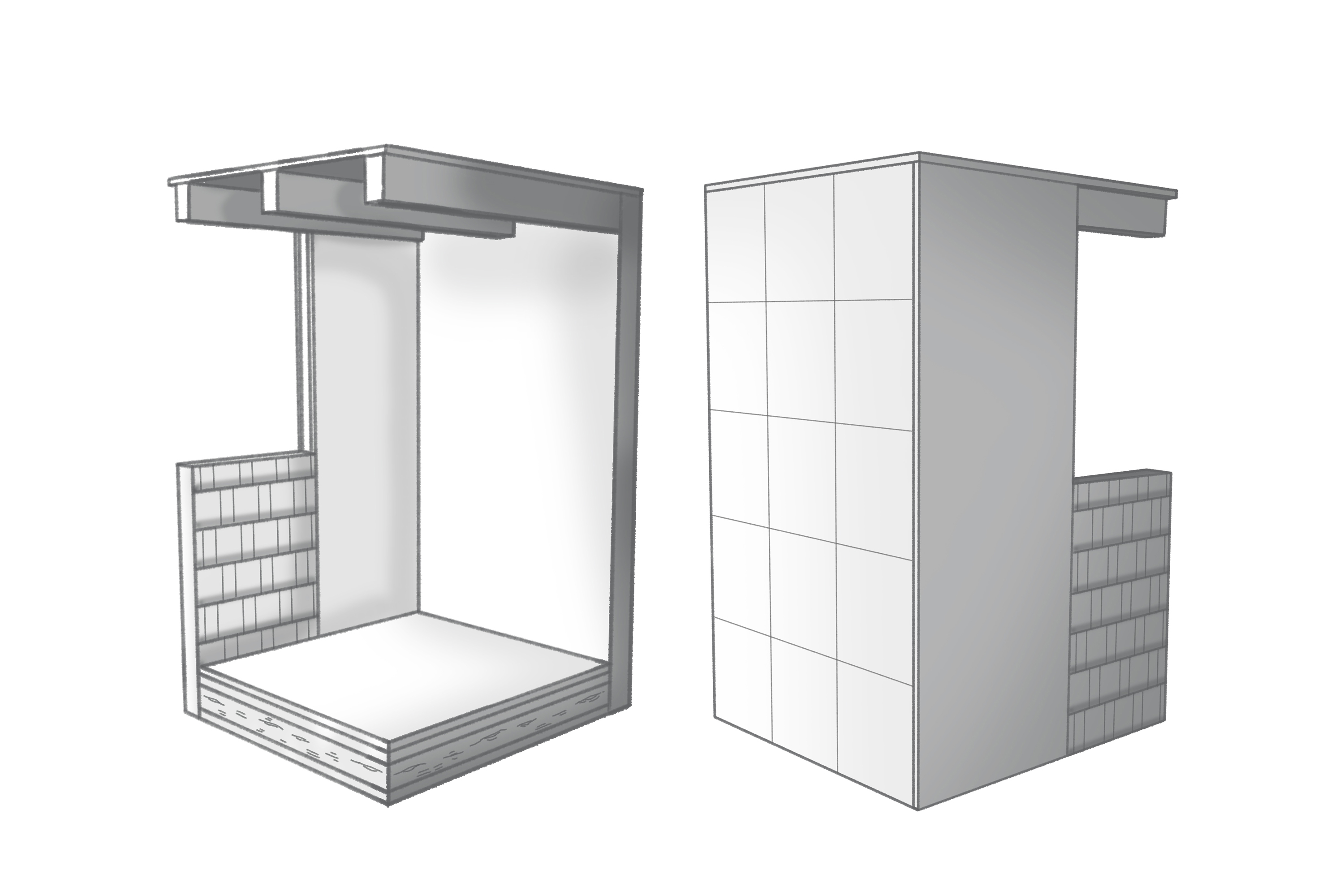

In a current research project, researchers at the Fraunhofer WKI are determining how beech wood, which will be increasingly available in the future, can be used as wood-fiber insulation material in the form of mats or foams. At LIGNA 2023, the researchers will present one possibility: a thermal-insulation wall made from hollow bricks filled with insulation mats composed of beech-wood fibers. The brick wall is part of the “Multi-material model Wall I Ceiling I Roof”. Industrial partners will test the insulating materials developed at the Fraunhofer WKI to ensure their practical suitability. The project team is working on an economically attractive solution for the production of wood-fiber insulation materials from beech wood for the construction industry.

Flexible wood-fiber mats are ideally suited for the thermal insulation of buildings - for example as between-rafter insulation or as a filling material for thermal-insulation bricks. Until now, such wood-fiber insulation mats have been manufactured primarily from softwood. As a result of climate change, this will be available in significantly smaller quantities in the future.

“In order to ensure a reliable raw-material basis for wood-fiber insulation materials for the construction industry, we are currently developing – in collaboration with industrial partners – insulation mats and novel wood-foam granules made from beech-wood fibers. Our project objective is the establishment of a pilot plant for the production of insulation mats, which we are developing and optimizing in the project using the example of brick filling. In this way, we are creating a sustainable perspective for the construction industry as well as a high-quality utilization possibility for beech wood. As a result of climate-induced forest restructuring, beech wood will be increasingly available in the future,” reported Dr. Nina Ritter, Group Leader at the Fraunhofer WKI.

In collaboration with the project partner Loick Biowertstoff GmbH, the researchers are investigating which processes can be used to break down beech wood into fibers for the production of insulation mats and wood-foam or wood-foam granules. Amongst other things, low-value damaged wood is to be used for this purpose. “In order to achieve the desired structure, strength and elasticity in the fiber mats, we want to adapt a commonly used manufacturing process for wood-fiber insulation materials, in which supporting fibers made from thermoplastic material are introduced. Bicomponent fibers are generally used for this purpose; these consist of a permanently elastic inner part and a hotmelt adhesive jacket,” explained Dr. Ritter.

For the production of the wood foams, the researchers employ a process previously developed at the Fraunhofer WKI. In order to produce wood-foam granules, the manufactured wood foams are subsequently broken down into granules using various crushing units and, if necessary, additionally hydrophobized. The goal is a pourable (solid or liquid) material for the brick filling.

As a specific application example for the new beech insulating materials, the scientists would like to test the filling of hollow bricks in this project in cooperation with the brick manufacturer Bellenberg. Amongst other things, they are thereby pursuing the goal of optimizing the adhesion between the brick surfaces and the insulation material so that no insulation material can escape when the bricks are cut or drilled.

“In collaboration with the company Bellenberg, we are investigating not only the fire behavior but also the recyclability of the insulation-filled bricks. In cooperation with the company Loick, we will develop and construct a functional pilot plant for the production of insulation material made from beech wood. The aim here is the development of an economically viable plant concept. Parallel to the development of the insulation materials, Loick will also determine the material and energy requirements for the production of the insulation materials,” said Dr. Ritter, describing the cooperation with the partners.

At the Fraunhofer WKI, the scientists will test the beech-based insulation materials (such as mats, boards, foams and granulates) with regard to their physical-technological properties and their utilization in bricks and wall structures.

Upon successful completion of the project, an economically attractive solution for the production of wood-fiber insulation materials from beech wood will be available. This is an important step towards securing and broadening the raw-material base in view of the forest restructuring resulting from climate change. Furthermore, the development of innovative wood-foam granules made from beech wood opens up new application possibilities in the field of filling materials, for example in thermal-insulation bricks with small, irregular cavities. In order to exploit the resource “beech wood” even more efficiently, it would also be conceivable to utilize the new wood-foam granules as a filler for transport packaging.

Experience us live at LIGNA 2023

The Fraunhofer WKI will be exhibiting the “Multi-material model Wall I Ceiling I Roof”, with the innovative wall made from thermal-insulation bricks, at LIGNA 2023. The Fraunhofer WKI will be presenting its innovations in Hall 26, Stand B 78. Co-exhibitor is the International Association for Technical Issues Related to Wood (iVTH).

Further information about the exhibition stand: www.wki.fraunhofer.de/en/ligna-2023

LIGNA is the world’s leading trade fair for tools, machinery and equipment for woodworking and wood processing and will be held in Hanover from 15th to 19th May 2023.

Funding

The German Federal Ministry of Food and Agriculture (BMEL) is funding the project via the project management agency Fachagentur Nachwachsende Rohstoffe e. V. (FNR). The project is listed in the FNR funding database (funding codes 2221HV003A to 3C).

Last modified:

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research