#WeKnowWood: Pine expertise of the Fraunhofer WKI at LIGNA 2023

By means of a wall made from a multi-layer composite material as well as a ceiling beam, researchers from the Fraunhofer WKI will be demonstrating utilization possibilities for pine wood at LIGNA 2023. The demonstrators are the result of two current research projects at the Fraunhofer WKI. The “wood of the future” pine is one of the most important tree species in Northern Germany in terms of area covered and copes relatively well with climate change. As pine wood will be available in greater quantities in the future, the researchers are working on the development of application fields with high revenue potential for the construction and automotive industries.

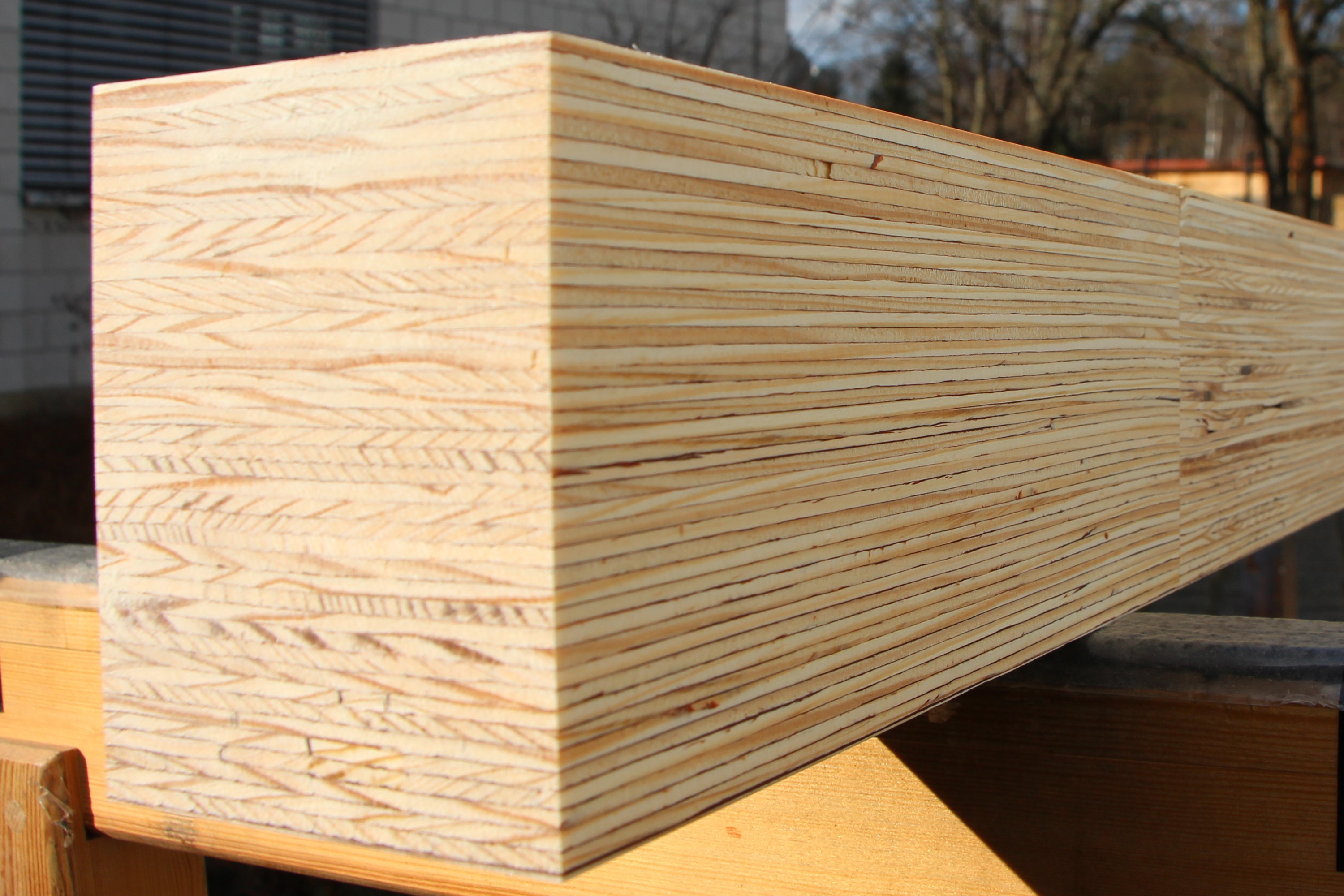

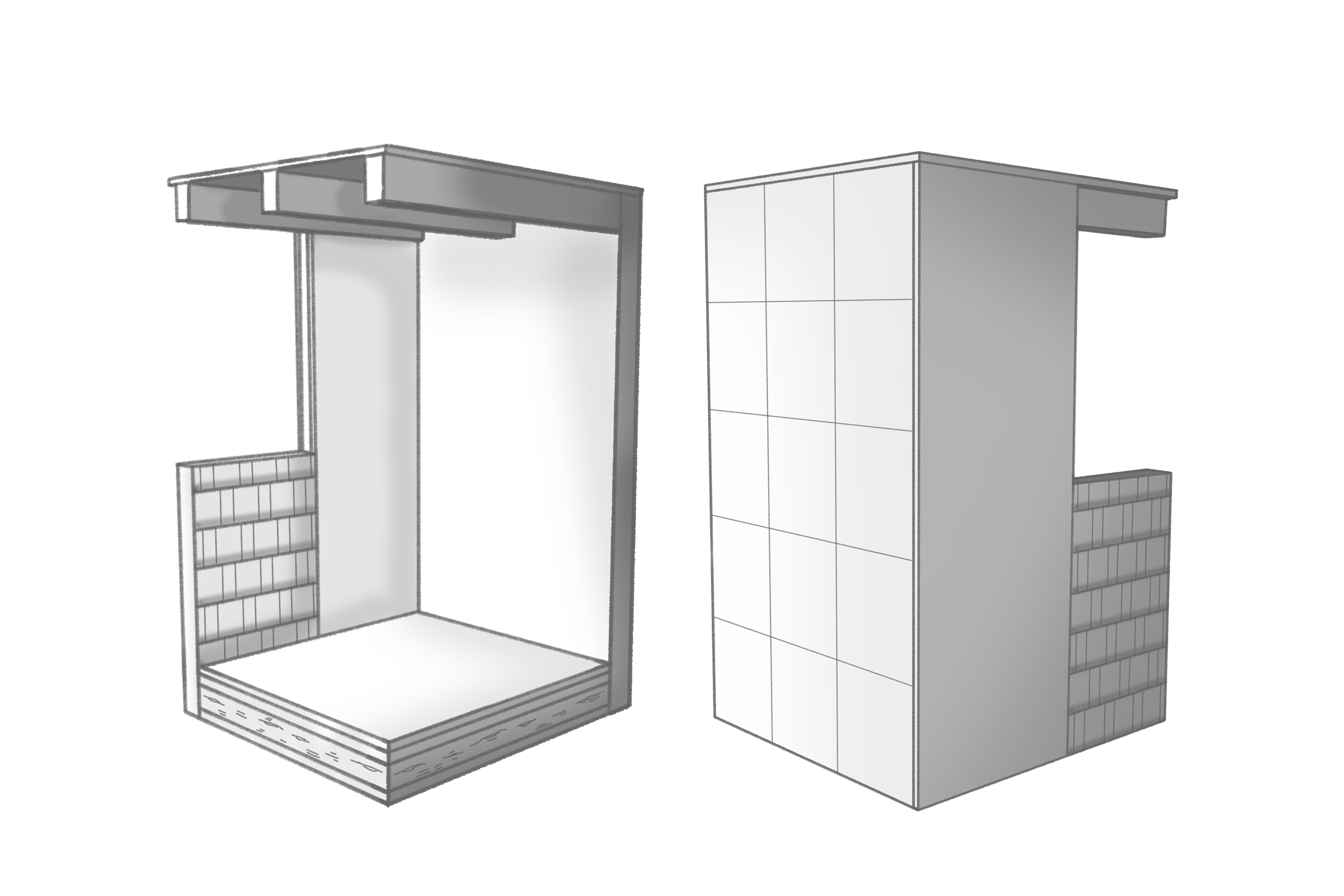

At LIGNA 2023, which is currently taking place, the Fraunhofer WKI is exhibiting the “Multi-material model Wall I Ceiling I Roof”, in which a wall and a ceiling beam are made from pine laminated veneer lumber. In light of climatic changes, Scots pine is considered as the “tree of the future”. Pine trees were planted after World War II, particularly in Northern Germany, and are now reaching harvest maturity at relatively the same time. As not all trees can be felled and processed at the same time, large-dimension pine wood will be available in the future. Researchers at the Fraunhofer WKI, in collaboration with project partners, are currently investigating the optimal application possibilities of pine wood and large-dimension pine wood within the scope of two research projects.

Digital value chain for pine-based timber construction – “DiKieHo”

The Fraunhofer WKI is working together with the Technische Universität Berlin and the Fraunhofer Institute for Production Systems and Design Technology on an optimized, future-oriented value-added system for multi-story timber construction from pine wood in the Berlin-Brandenburg region. “The aim of the research in our technical center is to develop new wood-based materials from regional pine wood. The Berlin-Brandenburg region was chosen for the analyses in the project because it is exemplary in terms of the prevalence and utilization of pine wood,” explained Dr. Dirk Berthold, Head of Department at the Fraunhofer WKI.

Using a systemic approach, the researchers are investigating the interaction of material and information flows between the participants. They thereby identify potentials for cooperation and their effects within the industrial context of multi-story timber construction. The research results are to be adapted to further target regions and scaled up accordingly in the future.

In the value chain, the researchers are examining aspects such as the use of regional raw materials, the optimal utilization of product ranges, and the creation of high-quality timber construction elements. Furthermore, the erection of climate-friendly buildings, the strengthening of a climate-neutral metropolitan region and the establishment of effective closed resource cycles are being analyzed.

Multi-layer composites from large-dimension pine-wood stocks – “KiefernStolz”

“Our ‘KiefernStolz’ (pine pride) project addresses the high-quality utilization of large-dimension pine wood. This will be available in large quantities in the future, but experience in its utilization is extremely limited. We therefore want to test, within the project, how these stocks can be processed in a way that optimizes value creation,” explained Dr. Berthold.

The project partner, Nordwestdeutsche Forstliche Versuchsanstalt (northwest German forest research institute), is investigating the utilization potentials and silvicultural strategies for the optimal exploitation of large-dimension pine wood. At the University of Göttingen, analyses of the value-added potential of large-dimension pine wood in northwest Germany are being carried out, and the safe and environmentally friendly harvesting of large-dimension pine wood is being investigated, thereby taking into account the entire process chain. Products made from large-dimension pine wood are also being identified and developed there.

In the technical center of the Fraunhofer WKI, researchers are developing multi-layer composites from large-dimension pine-wood stocks resulting from the investigations of the project partners. These include the typical strength and quality classes that are to be expected.

“Crucial for the success of our project is the recording of the specific properties of the pine as well as its quality classes, and the corresponding adaptation of the process control. The wood species and quality have an influence on the technical processing. In glued pine wood, the high resin content can cause problems in the glue joint or surface through resin discharge and delamination. We will therefore test a variety of industrially applied adhesive systems for the bonding of the pine veneers,” said Dr. Nina Ritter, Group Leader at the Fraunhofer WKI, in her explanation of the procedure.

Dr. Berthold added: “We are also using adhesives on the basis of MDI prepolymers and urethane polymers, which are being investigated and modified at the University of Göttingen within the framework of the overall project. They could prove to be technically advantageous and are formaldehyde-free. The aim is to enable wood-based-material manufacturers to convert their production lines from spruce to pine without major process modifications.”

In order to make the most efficient use of the accruing pine wood, the project team is testing the production and processing of sapwood and heartwood veneers. Panel-shaped materials and components are produced by the researchers using the hot pressing process. A wall made from laminated veneer lumber (LVL), in which the veneers are glued lying parallel to each other, has already been successfully produced and is currently on display at LIGNA 2023.

The achievable material properties of the various product types with regard to hygric and mechanical stress will be analyzed and optimized by means of standardized tests in the further course of the project.

Experience us live at LIGNA 2023

The laminated veneer lumber wall and a ceiling beam made from pine will be presented within the framework of the “Multi-material model Wall I Ceiling I Roof” at LIGNA 2023. The Fraunhofer WKI will be presenting its innovations in Hall 26, Stand B 78. Co-exhibitor is the International Association for Technical Issues Related to Wood (iVTH).

Further information about the exhibition stand: www.wki.fraunhofer.de/en/ligna-2023

LIGNA is the world’s leading trade fair for tools, machinery and equipment for woodworking and wood processing and will be held in Hanover from 15th to 19th May 2023.

Funding

The project “DiKieHo” is funded by the German Federal Ministry of Food and Agriculture (BMEL) via the project management agency Fachagentur Nachwachsende Rohstoffe e. V. The project is listed in the FNR funding database (funding codes 2221HV082A and B).

The project “KiefernStolz” is funded by the “Waldklimafonds” (forest climate fund), a joint funding program of the German Federal Ministry of Food and Agriculture (BMEL) and the German Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection (BMUV). The Fachagentur für Nachwachsende Rohstoffe e. V. (FNR) is also responsible for the project management. The project is listed in the FNR funding database (funding codes 2220WK01A3 to E3).

Last modified:

Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research