Here is a small selection of our research projects.

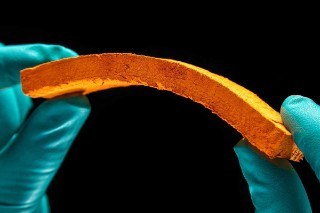

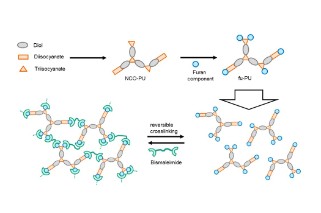

Particle boards are a sustainable and inexpensive construction material for houses and furniture. They can be produced from regionally available wood residues and recycled waste wood. Through this research project, particle boards will become even more sustainable. In collaboration with industrial partners, we are developing particle boards that are produced using a new kind of adhesive which should not contain any health-critical formaldehyde and which consists entirely of biogenic raw materials. Furthermore, we are conducting tests to determine whether the particle boards can be produced using alternative types of wood, which will be increasingly available in the future as a result of forest restructuring.

more info Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research