Here is a small selection of our research projects.

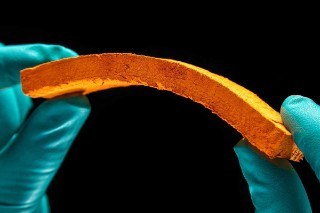

The wood constituent lignin accrues in large quantities as a by-product of pulp and paper production. In collaboration with industrial partners, we are developing a high-performance bio-foam from lignin. In order to demonstrate its market potential, the lignin foam is being processed into molded parts for the automotive industry within the scope of the project. These parts are to be utilized as the core in car bumpers. Petrochemical foam materials could also be replaced by climate-friendly lignin foams in numerous other applications - for example in packaging, insulation materials or as a core material in wind-turbine rotor blades.

more info Fraunhofer Institute for Wood Research

Fraunhofer Institute for Wood Research